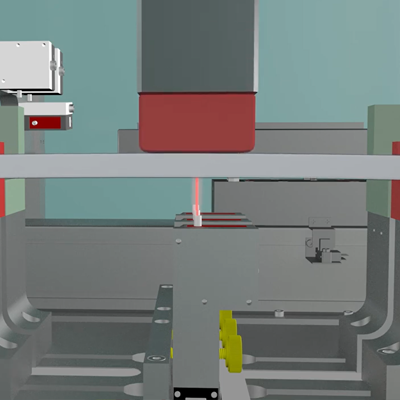

Straightening work station

In the world of manufacturing, metal components that should be perfectly straight and flat sometimes end up bent, warped, or skewed due to various factors like heat treatment or improper storage. When the performance and fit of your components hinge on their straightness and flatness, Promess has the solution for you, the Promess Semi-Automated Straightening Work Station.

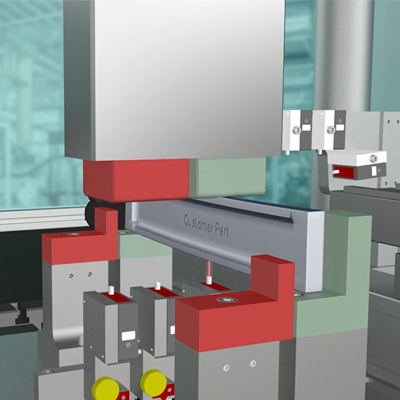

With the operator’s activation of two-handed anti-tie down cycle-start buttons, the press and torque unit respond according to precise calculations based on the initial measurement. This process is the epitome of efficiency and precision working hand in hand.

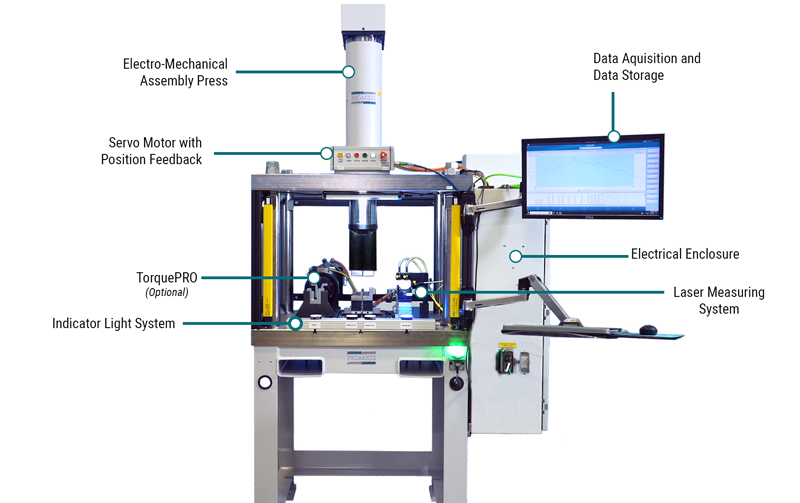

Complete Station

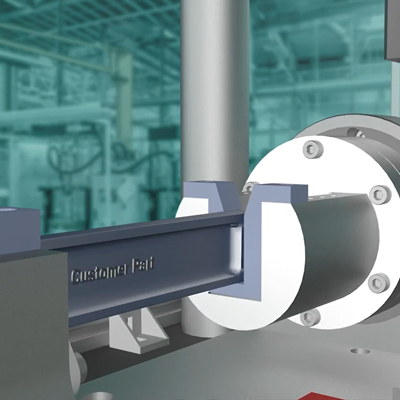

Comprises an Electro-Mechanical Assembly Press (EMAP) and TorquePRO, accompanied by expertly designed fixtures and integrated safety features include light curtain and two hand tie down.

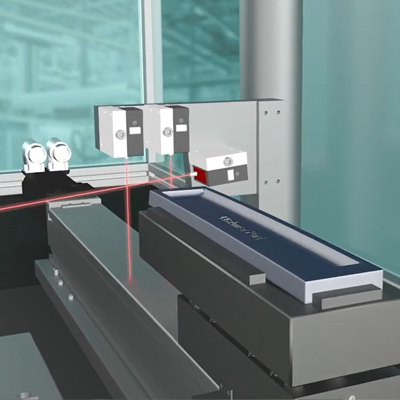

Smart Measuring

Features a three laser distance sensors on two axes to measure and assess flatness and straightness along both the short and long axes.

Software

The Promess software takes out all the guesswork, using the measurements from the laser the software communicates to the operator through an indicator light system where the part should be placed.

Straightening Work Station Capabilities

Smart Measure

Straighten

Part Upright

Straighten

Part Flat

Untwist

Applications across a range of industries

Investment Casting

Medical

Aerospace

Automotive

Defense

Do you have a part that needs straightening?

Collaborate with our Straightening group to discuss your component and process needs.