Robot Press

Robot Press L-Series

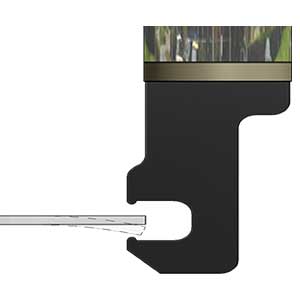

The Robot Press L-Series is a line of lightweight press systems intended for use as end effectors in robotic assembly applications.

The Robot Press is intended for use in flexible assembly cells where the process requires that the press be brought to the part rather than bringing the part to the press. Part changes or adjustments can be made by changing robotic positioning rather than swapping expensive tooling and die sets, or changing machine designs.

Controllability

- Press motions are fully programmable

- Integrated monitoring and motion control

- Force Feedback

- Presses are equipped with force and position sensors to support intelligent assembly operations

Featuring

- Lighter press design for mobility

- Lubrication system that allows automatic greasing of the ball nut

- Hardened cap to take load, instead of transferring to robot axis

- Robot and flange mounting

Robustness

- Rock-solid mechanical design – use over multiple projects, compounding ROI

- Electronics and mechanics designed to last millions of cycles

- Overload protection built into software to eliminate damaging equipment

FEATURES

Capabilities

Push or pull with equal accuracy

360° mounting orientation

Easy to use Windows software

Capabilities ranging from less than an ounce to over 200,000 lbs.

Data

Data acquisition and storage

In-process verification and

monitoring

Integrated load cell

Network multiple systems

Robustness

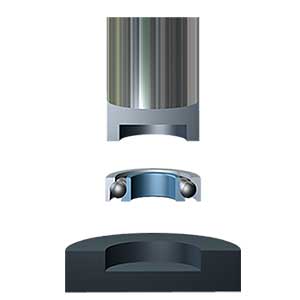

Ball screw design that features

dynamic press load capacity 2.5 to

3 times greater than the stated

load capacity

Servo system sized to reach rated press load capacity in the continuous current range of the motor & drive

Do You Have an Application?

Talk to one of our expert engineers or learn more about proving your

application in our Process Development Center.

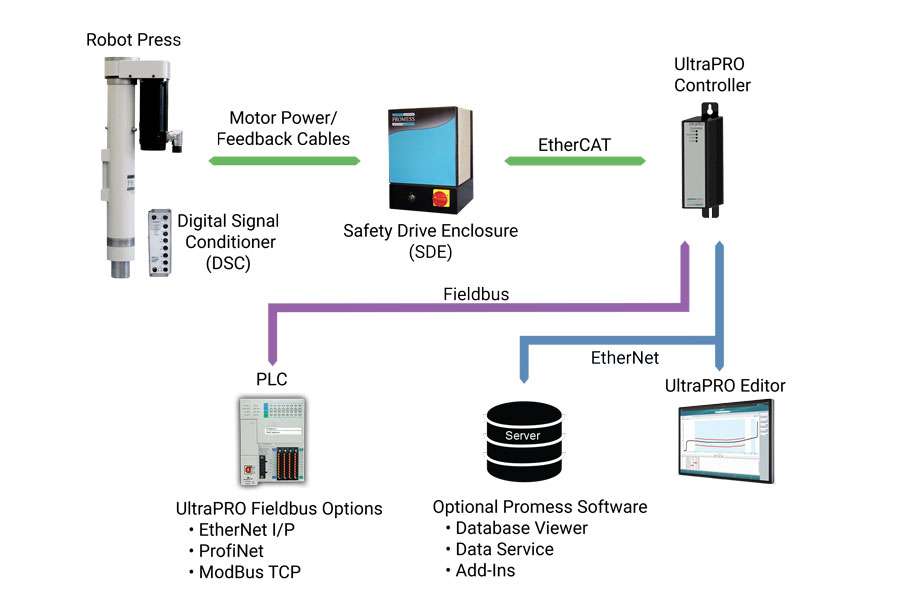

System Powered By Promess Software

Promess powerful system software solution offers custom commands, flexible configurations, and adjustable features to address your specific needs.

Features of Promess Software

- Easy to Use

- Traceability

- Data History

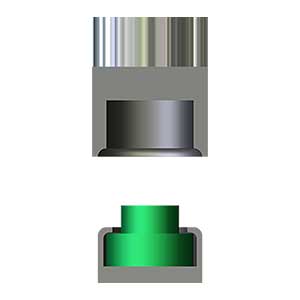

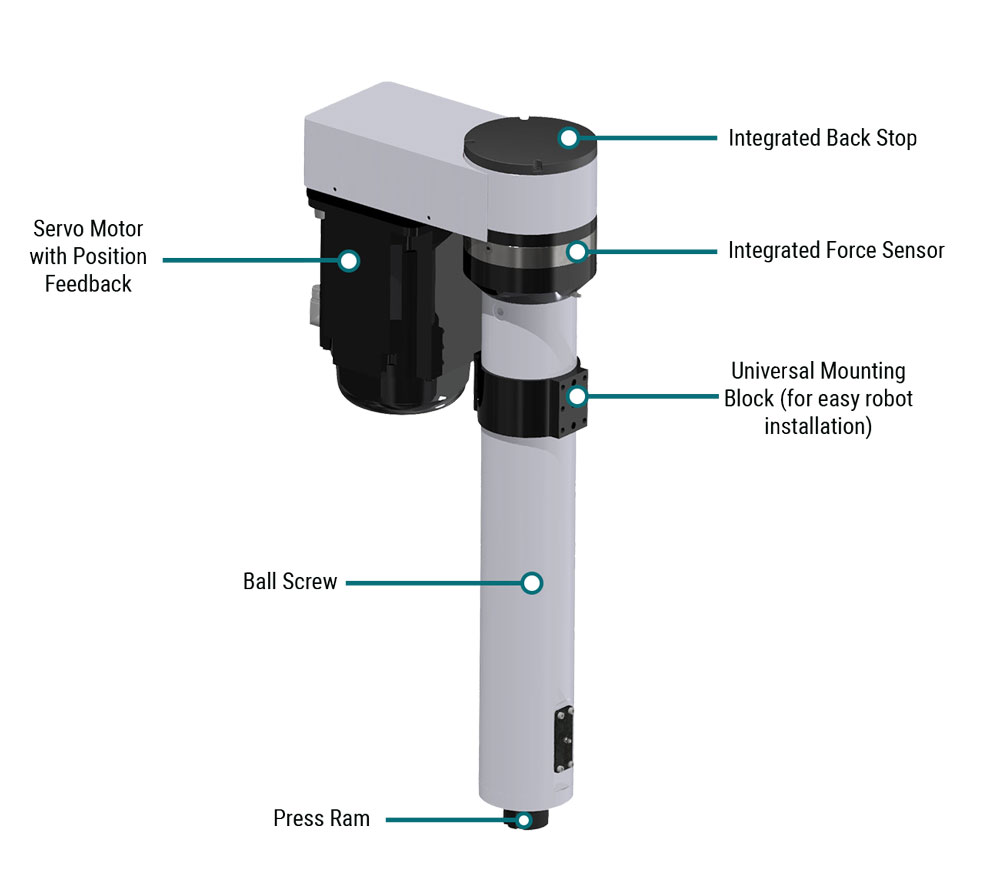

Robot Press Mechanics

Complete System

System Includes

- Fully Programmable Axis of Motion

- Integrated Force Transducer

- Promess Controller with Windows Based Software

- All Required Drives, Electronics & Cables

- Integrated Back Stop Motor Mounting Package

- Mounting Block for Easy Robot Installation

Options

- Additional Load Cell Ranges

- Additional Stroke Lengths

- Single Cable Feedback

- Absolute Encoder

Looking for a More Tailored Solution?

Looking for a plug and play systems that allows you to be up and running same day as delivery? Learn more about our Work Stations.

Robot Press L-Series Sizing

| FORCE (kN) | STROKE (mm) | SPEED (mm/sec) |

|---|---|---|

| 1 | 100, 300 | 200, 150 |

| 10 | 200, 400 | 300 |

| 20 | 200, 400 | 300 |

| 30 | 200, 400 | 300 |

| 50 | 200, 400 | 300 |

Are you unsure about force requirements – visit our Process Development Center

Prove Out Your Process

The PDC is available to you for help verifying your process at no cost to you. Bring in or send in your parts and work with an engineer to find the technology best suited for your application.

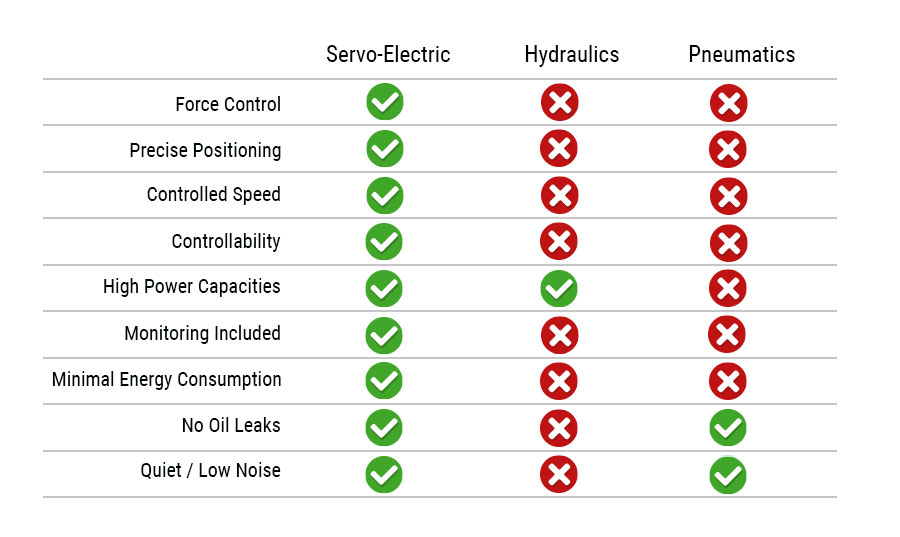

How We Compare to Other Technologies?

When looking for equipment to assemble your parts there are a lot of options. Learn more about how Promess compares to other press technologies.

Resources

Downloads

Webinars