ELECTRIC PRESS WORK STATION

Electric Press Work Stations

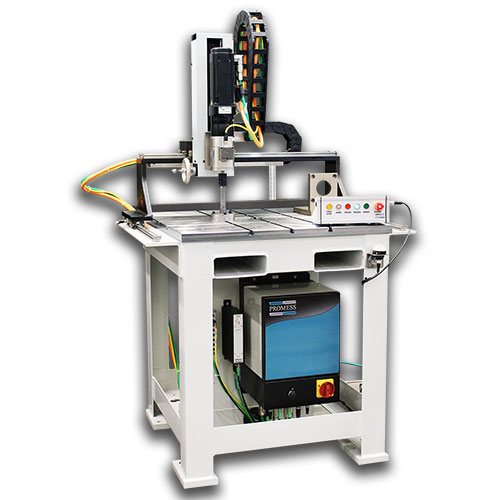

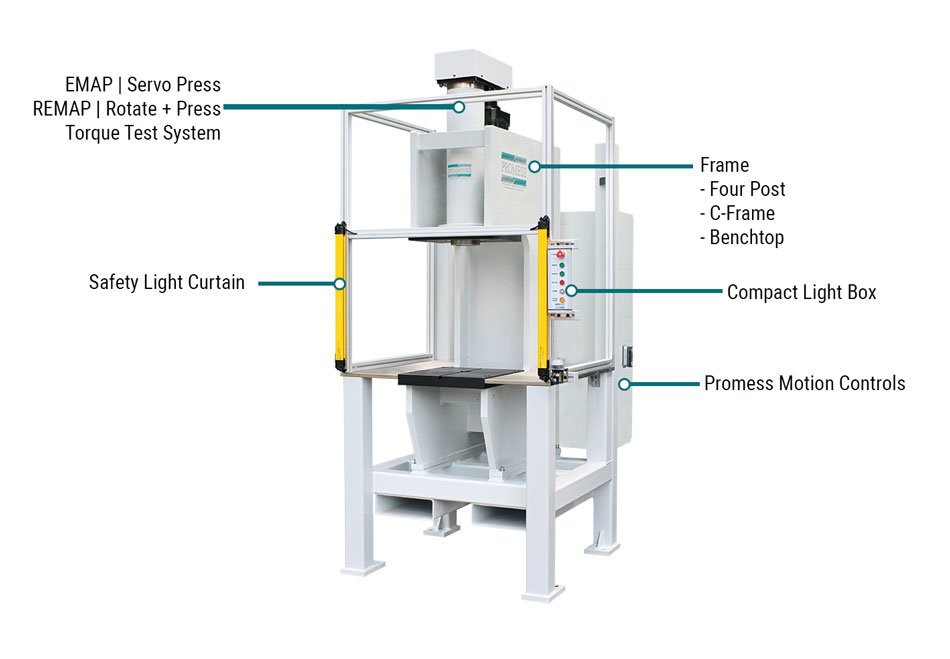

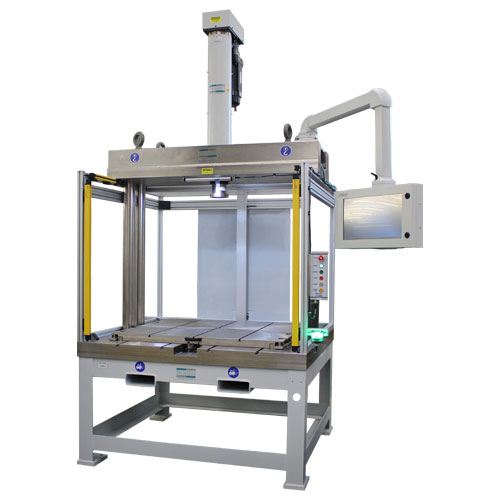

The Promess Electric Press Work Station is a fully electric stand-alone unit with an integrated Promess Electro Mechanical Assembly Servo Press (EMAP), REMAP or TorquePRO.

The Promess Work Station offers you the most competitive, accurate, and efficient solution to any assembly requirement.

Controllability

- Integrated with EMAP, REMAP or TorquePRO

- Simple Programming

- Position Sensing

- Force Feedback

Simple Integration

- Can be used by an operator or automatically loaded

- Simple controls – No PLC needed

- Tailored foundation for assembly or test applications, in both production or R&D

- Plug and Play – Add power and tooling and run parts within hours

Scalability

- Standard Station sizes with short lead times

- Easily add capacity to any production scenario

- Repurpose as production numbers scale down

Electric Press Work Station Mechanics

Flexible Configurations and Sizing. Contact us regarding your application.

VIDEO: Work Station

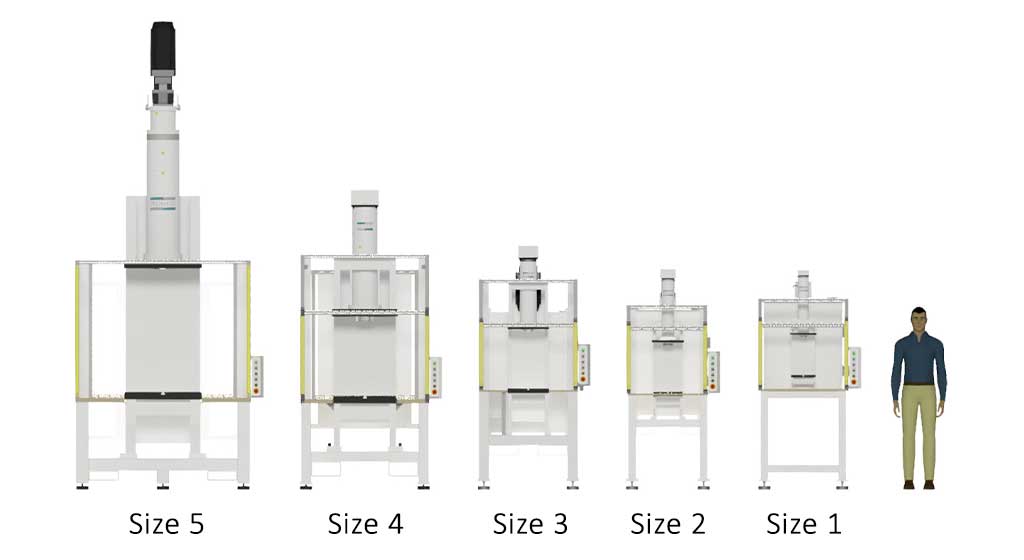

Electric Press Work Station Standard Frame Sizes

Sizing by Motion

Electric Press Sizes

Electric Press Sizes

| Station Size | Force (kN) | Stroke (mm) | Speed (mm/sec) |

|---|---|---|---|

| Size 1 | 1 | 300 | 200 |

| 3 | 300 | 200 | |

| 5 | 350 | 200 | |

| 8 | 350 | 200 | |

| 12 | 350 | 200 | |

| Size 2 | 20 | 350 | 200 |

| 30 | 350 | 200 | |

| Size 3 | 40 | 330 | 200 |

| 60 | 330 | 200 | |

| 80 | 330 | 175 | |

| 100 | 330 | 200 | |

| 120 | 330 | 175 | |

| Size 4 | 160 | 400 | 100 |

| 300 | 400 | 100 | |

| Size 5 | 500 | 400 | 75 |

| 1000 | 400 | 50 |

Press and Rotate Sizes

REMAP Sizes

Linear Axis

| Force (kN) | Stroke (mm) | Speed (mm/sec) |

|---|---|---|

| 1 | 100 | 200 |

| 5 | 200 | 200 |

| 12 | 400 | 200 |

| 20 | 400 | 200 |

| 30 | 400 | 175 |

| 40 | 400 | 200 |

| 60 | 400 | 150 |

Rotational Axis

| Torque (Nm) | Speed (RPM) |

|---|---|

| 20, 50, 100 | 250 |

| 20, 50, 100, 200 | 250 |

| 20, 50, 100, 200 | 250 |

| 20, 50, 100, 200 | 250 |

| 20, 50, 100, 200 | 250 |

| 20, 50, 100, 200 | 250 |

| 20, 50, 100, 200 | 250 |

Torque Sizes

Torque Sizes

| Torque Capacity (Nm) | Torque Capacity (lb-in) | Max Speed (RPM) |

|---|---|---|

| 5 | 44 | 250 |

| 20 | 177 | 250 |

| 50 | 442 | 250 |

| 100 | 885 | 250 |

| 200 | 1,770 | 250 |

| 500 | 4,425 | 100 |

| 1,000 | 8,851 | 75 |

| 2,500 | 22,127 | 20 |

| 5,000 | 44,254 | 10 |

| 10,000 | 88,507 | 4 |

Tailored Solutions

Promess has the ability to tailor our Work Stations to fit your applications, with our extensive experience and expertise we can find a solution for you.

Platen Press

Uniform controlled loads over a large area, capable of forces up to 2,000 kN over an area sized to fit the application.

Gantry Press Work Station

The Gantry gives the Promess Work Station ability to position the EMAP anywhere within the Work Station’s envelope.

4-Post Work Station

4-Post Work Station with Load/Unload Moving Bolster Plate Enabled and Monitored

WHY WORK STATIONS?

- Easy integration, be up and running same day.

- Lower energy consumption and small footprint.

- Scalable to your application, develop then ramp up for production

- Faster lead times

Accessories

Promess has add ons availabile to fit your application. Depending on the application needs the Work Station can be tailored to fit these needs.

Safety Drive Enclosure

The PRO-SDE is the easiest way to add motion control capabilities paired with data acquisition and analysis to any current assembly or testing process.

PRO-Bot2x

Parts can be easily transferred to load/unload positions where they can be interfaced manually or via automation.

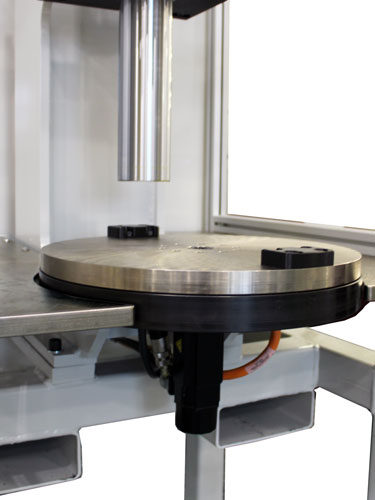

Index Table

The Index Table was designed to add part loading and indexing capabilities to any Promess Work Station, the unit features load bearing capabilities.

Gantry Station

The Gantry gives the Promess

Work Station ability to position the EMAP anywhere within the Work Station’s envelope.

Prove Out Your Process

The PDC is available to you for help verifying your process at no cost to you. Bring in or send in your parts and work with an engineer to find the technology best suited for your application.