Manufacturing Systems for Mission-Critical Defense Applications

Press and Torque in Defense Assembly

Years of experience with the defense and aerospace industries, Promess understands the needs of those manufacturing for the American war fighter. The programmability of our systems gives the flexibility to tackle any application from munitions assemblies to special composite processes. Our in-process monitoring and motion control ensures that only quality parts make it down the assembly.

Precision Press Systems

Our closed-loop press and torque systems are designed to ensure accuracy, repeatability, and durability in the most demanding defense applications. Our integrated in-process monitoring and control software provides real-time feedback for each assembly, allowing customers to make real-time adjustments for the optimal part assembly. With decades of experience, our highly skilled engineering team offers expert application assistance and support.

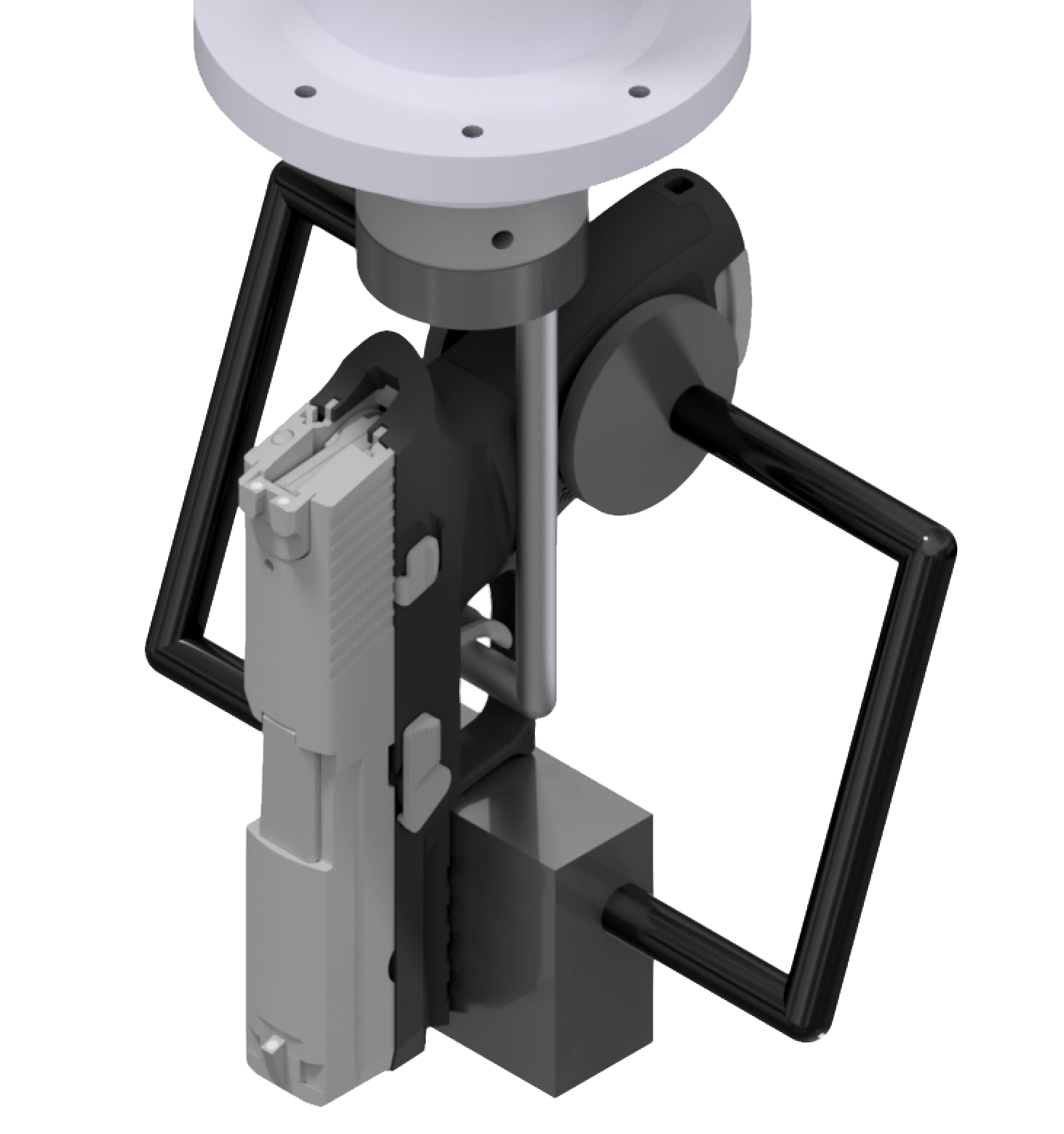

Promess Tailored Hazardous Location Press

Manufacturing Systems for Hazardous Environments

Promess offers high-precision force and torque systems that enable precise measurement and control in critical defense operations, ensuring optimal performance and safety in normal and hazardous manufacturing locations. Both tailored and standard solutions are available. Our application specialists are available today to discuss requirements.

Manufacturing Flexibility and Longevity

Whether you need to make a few assemblies a month or a million or more, Promess has you covered. Our systems allow you to quickly change between assembly recipes, supporting both low and high volumes of production. Robustness is a core feature of our systems. This reliability paired with minimal required maintenance, allows most of our programs to run well past their intended timelines, even benefiting future programs with little further investment.

Defense: Press & Torque Applications Video Examples

Defense Applications

- Nuclear fuel compaction

- Ordinance charge assembly

- Carbon fiber processing

- Firearm testing

- Vehicle component assembly

- More

Application: Trigger Pull Test

Promess Servo Press was used to achieve consistent reliable assembly on each and every handgun.

Application: Composite Compression

Utilizing the Promess Platen Press the manufacturing was able to monitor and control the force while maintain the speed required for the application.

In-Process Motion Control Solutions

Electro-Mechanical Assembly Press

The Promess Electro-Mechanical Assembly Press (EMAP) is a fully electric, programmable motion controlled ball screw press with integrated motion control.

Rotational Electro-Mechanical Assembly Press

The REMAP provides fully programmable, precise and independent control of both linear and rotational motion into a single unit.

Electric Press

Work Stations

The Promess Electric Press Work Station is a fully electric stand-alone unit with an integrated Promess Electro-Mechanical Assembly Press, REMAP or TorquePRO.

TorquePRO Systems

The Promess TorquePRO system is a fully electric, programmable, rotational actuator. Built to control torque and position in production and test environments.

Discuss your application with a Promess Assembly Expert!

We’re here to help you with your application. Whether you have questions, need more information, or are ready to get started, our team is here. Contact us today.