Case Study #1875 | EMAP

VALVE SEAT & GUIDE ASSEMBLY

Challenge

The customer required precision force and distance control along with sophisticated analysis to assemble valve seats and valve guides to precise tolerances and give their customer data to prove it.

Additionally, the customer required a flexible assembly system that could accommodate many different part models, adopt to engineering updates and part improvements that could affect the assembly characteristics, along with the performance to handle the rigors of production manufacturing.

Solution

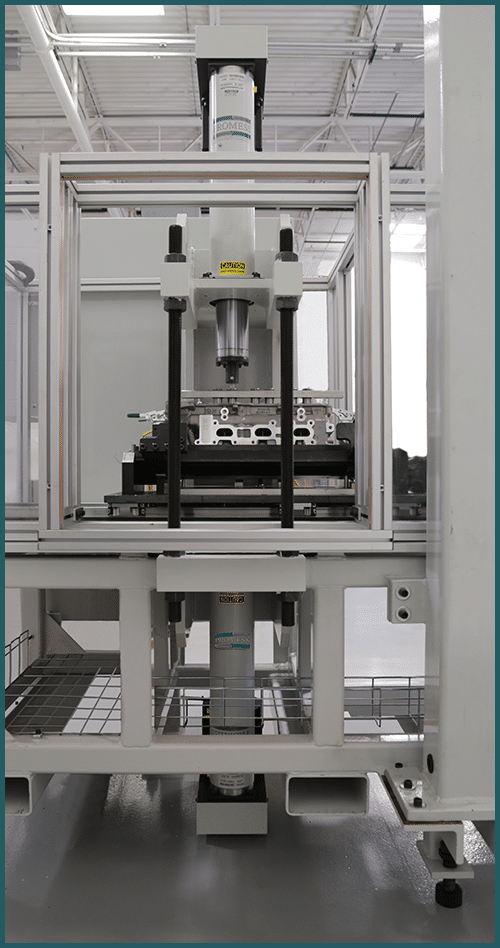

The Promess UltraPRO system with EMAP press was chose for its precise control and almost infinite programming capability.

The UltraPRO controller is easily integrated into flexible assembly cells, large transfer lines or manual workstations. The UltraPRO system easily handles program changes with its simple but powerful programming style.

Couple that with its ability to interface with different data storage software packages and you have a very powerful servo-controlled press system.

Results

The result, each part is assembled exactly the same, allowing the cylinder head to function to its peak performance along with the data for each assembly. Customer needs met and exceeded quickly, efficiently and with confidence to prove it.

Do You Have an Application?

Talk to one of our expert engineers or learn more about proving your

application in our Process Development Center.