Case Study #1635

Seat Recliner Mechanism Testing

CHALLENGE

In the automotive industry, ensuring the safety and reliability of every component is crucial. One of the most safety components in a vehicle is the seat recliner mechanism, which must meet customer functionality and government safety standards.

Manufacturers faced several key challenges in testing seat recliners:

- Stringent Compliance Requirements: Seat recliner mechanisms must adhere to both customer expectations and government safety regulations like the Federal Motor Vehicle Safety Standards (FMVSS).

- Comprehensive Testing Needs: Traditional testing methods lacked the ability to accurately measure multiple parameters such as torque, rotation angle, latch/unlatch effort, spring force, tooth engagement, and backlash—all critical to functionality and safety.

- Inconsistent Data & Traceability: Without precise control and certifiable documentation, manufacturers struggled with quality control, increasing the risk of defective components reaching production.

A more advanced, reliable, and efficient testing solution was needed to ensure compliance, detect failures early, and maintain product integrity.

SOLUTION

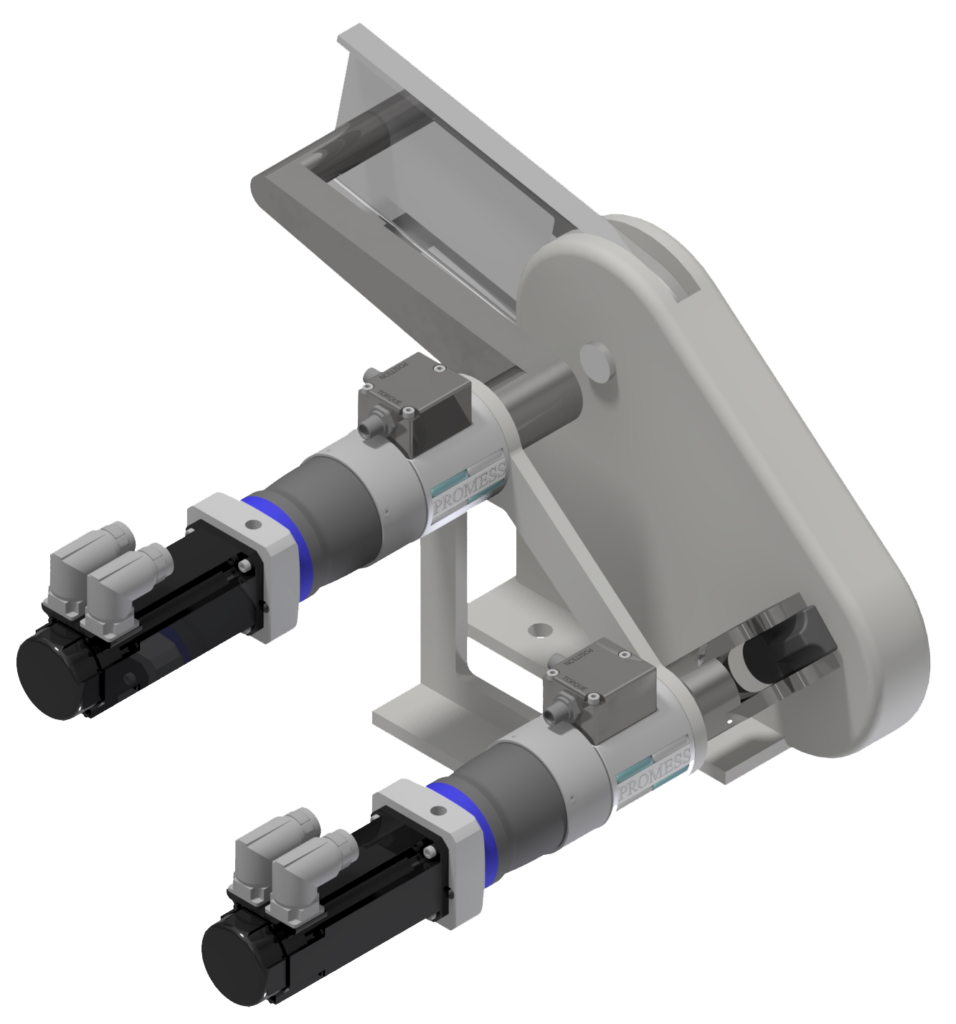

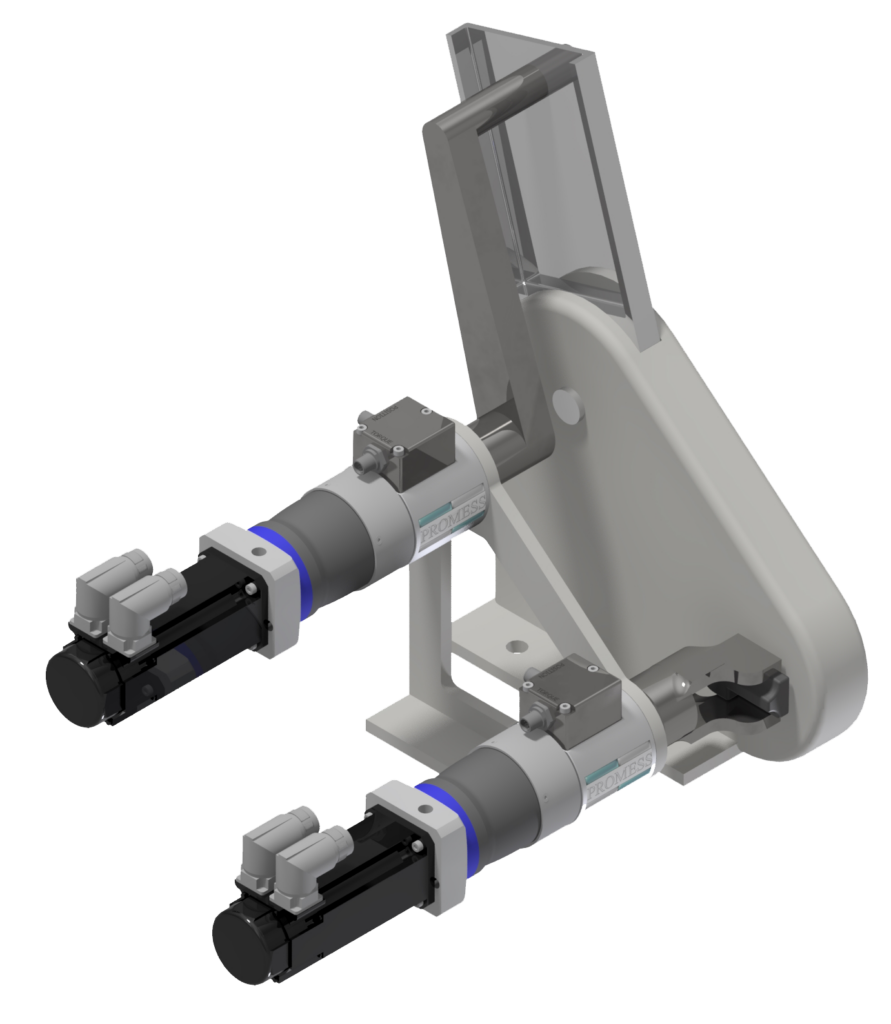

To address these challenges, the manufacturer implemented the Promess TorquePRO System, paired with a Promess Motion Controller. This solution provided a comprehensive, precise, and automated approach to seat recliner testing, delivering:

- Accurate Force Measurement – Measures the force required to move critical components like the latch lever and seatback recliner pivot across their full range of motion.

- Abnormal Force Detection – Identifies inconsistencies and out-of-spec parts, allowing early detection of assembly issues.

- FMVSS Proof Loading Verification – Ensures compliance with safety standards by verifying load capabilities in both directions.

- Precise Travel Range Measurement – Confirms the full recline and upright positions of the seat.

- Lock Position Testing – Applies a calculated bidirectional force to test component stability in the locked position.

- Spring Verification – Ensures seatback return springs and latch springs are present and functioning correctly.

- Comprehensive Data Collection – Maintains a detailed, traceable record of all test results for lot control, compliance, and process optimization.

By integrating effort and functionality testing with precision torque and angle control, the TorquePRO system improved seat recliner testing, providing a standardized and repeatable solution.

RESULTS

The implementation of the Promess TorquePRO System transformed seat recliner mechanism testing, leading to significant improvements in quality control and operational efficiency:

- Enhanced Accuracy & Compliance: Ensured that every mechanism met safety regulations with unparalleled precision.

- Early Defect Detection: Allowed manufacturers to identify and correct defects early, preventing faulty components from reaching the market.

- Complete Process Documentation: Provided certifiable data for regulatory compliance, ensuring full traceability.

- Improved Product Reliability: Increased customer confidence and satisfaction by guaranteeing that every seat recliner met exact performance standards.

- Optimized Production Efficiency: Reduced manual effort, rework costs, and testing time, leading to higher productivity.

The Promess TorquePRO System has become an essential tool in automotive safety testing, ensuring that seat recliners are manufactured to the highest standards of quality and reliability. By replacing outdated testing methods with advanced automation and precise force measurement, Promess has helped manufacturers build safer vehicles while improving efficiency and compliance.