Case Study #1720 | TorquePRO

Ensuring Quality & Performance in Desk Chair Torsion Bushings

CHALLENGE

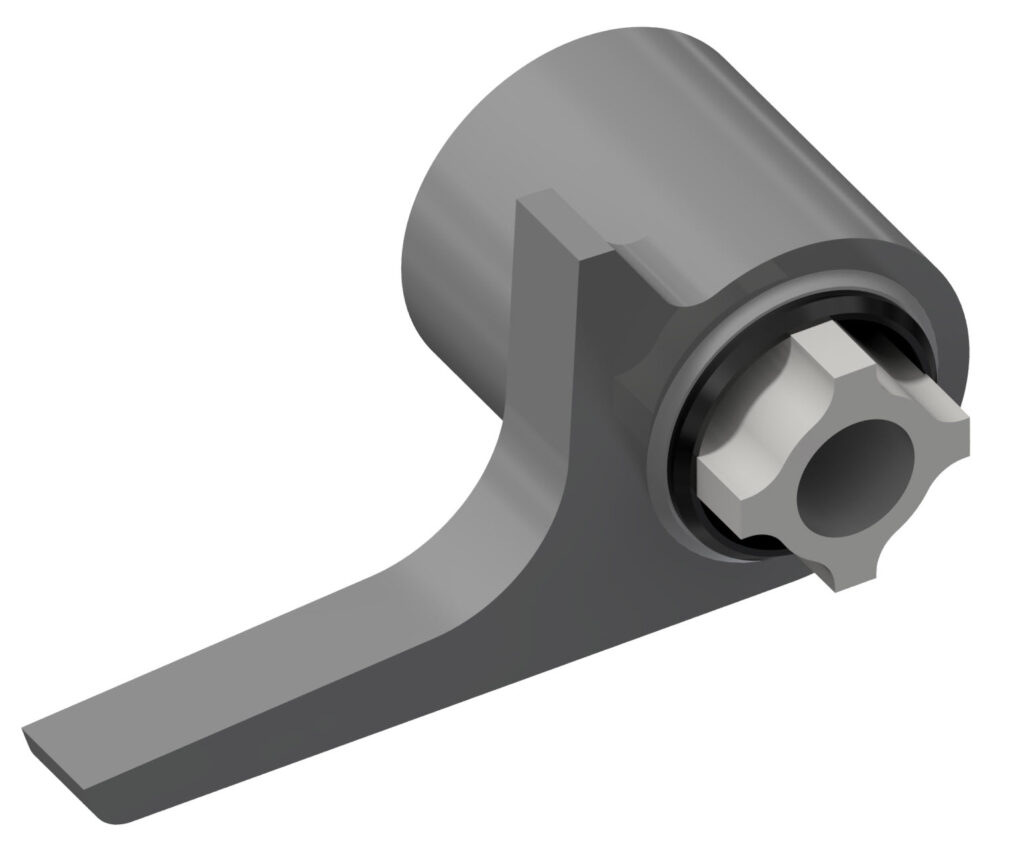

In the manufacturing of ergonomic desk chairs, one of the most critical components is the Torsion Bushing. This component enables users to lean back comfortably while preventing excessive stress that could damage or break the chair’s backrest. The manufacturer required a reliable, repeatable, and data-driven testing solution to ensure every torsion bushing met strict quality standards before being used in final assembly.

The manufacturer faced several challenges in their testing process:

- Torque Consistency – Each torsion bushing needed to be tested up to 100Nm to ensure it met force requirements.

- Complete Torque Curve Analysis – The system had to measure and analyze the entire torque curve of each part to detect any irregularities.

- Precise Rotational Positioning – The part needed to be rotated to an exact pre-load assembly position with precision.

- Data Acquisition & Traceability – The manufacturer required detailed records for each part tested, ensuring full traceability and process validation.

- Durability Testing – Each torsion bushing needed to be exercised 10 times before averaging the torque values to guarantee long-term performance.

To achieve these objectives, the manufacturer needed an accurate, automated solution that could measure, analyze, and document the torque characteristics of every part in real time.

SOLUTION

After evaluating multiple options, the manufacturer selected the Promess TorquePRO System for its real-time torque and angle monitoring capabilities, its ability to perform multiple tests per part, and its seamless data acquisition features.

The TorquePRO System was implemented with the following process:

- Operator Load & Initial Setup

- The operator places the torsion bushing into the test machine.

- The TorquePRO system automatically secures and aligns the part for precise testing.

- Torque Testing & Cycle Simulation

- The TorquePRO rotates the bushing multiple times, exercising it 10 times to simulate real-world usage.

- The system measures torque throughout the full rotation range, capturing a detailed torque curve for analysis.

- Pass/Fail Evaluation & Data Collection

- If the part meets all torque and rotational requirements, it is rotated into a precise pre-load position and moved to the next assembly stage.

- If the part fails to meet specifications, it is automatically flagged and removed from the process.

- The acquired torque and angle data is stored, allowing engineers to trace failures back to earlier processes and identify root causes of defects.

RESULTS

The implementation of the Promess TorquePRO System improved the manufacturer’s torsion bushing testing process, leading to immediate and measurable improvements:

- Enhanced Quality Control – Every torsion bushing was tested thoroughly, eliminating defective parts before they reached assembly.

- Comprehensive Torque Curve Analysis – The TorquePRO system captured and analyzed detailed torque characteristics, ensuring all parts met exact specifications.

- Precise & Repeatable Pre-Load Positioning – The system accurately positioned parts for pre-load assembly, eliminating manual inconsistencies.

- Increased Efficiency – Automated testing reduced operator variability and significantly improved throughput without sacrificing accuracy.

- Full Data Traceability – Every test result was logged and stored, giving the manufacturer detailed records for process validation and quality assurance.

- Faster Root Cause Identification – The system provided real-time feedback on failures, allowing engineers to quickly diagnose upstream process issues and prevent recurring defects.

By integrating the Promess TorquePRO System, the manufacturer optimized their torsion bushing testing process, ensured consistent product quality, and streamlined production. The ability to verify each part’s performance before assembly drastically reduced defects and improved overall product reliability.