Case Study #1650 | EMAP

Eliminating Threading Defects & Reducing Scrap with Promess REMAP

CHALLENGE

A manufacturer faced significant quality issues when assembling two sub-assemblies that needed to be threaded together and torqued to a precise value. Their existing process used electric torque-driver tools combined with air cylinders, but it had multiple inefficiencies:

- Thread Misalignment & Damage: The air cylinders would slam the parts together while the nut runner was spinning, hoping to catch the tiny threads. This often caused the system to rotate 4-5 times before successfully engaging the threads.

- Thread Shearing: A fraction of the time, the process would shear off part of the first thread, creating metal whiskers that could either fall out or damage the remaining threads.

- Hidden Defects: Damaged threads would often pass torque checks but fail the leak test at the final assembly station, leading to high scrap rates.

- Costly Waste & Downtime: The manufacturer was losing $90,000 per year due to scrap alone, not including labor costs and lost production time.

- No Rework Opportunity: Defective parts were scrapped entirely, as there was no way to correct the threading issue once assembly was completed.

The manufacturer needed a precise, intelligent solution that could eliminate thread damage, reduce failures, and optimize cycle time.

SOLUTION

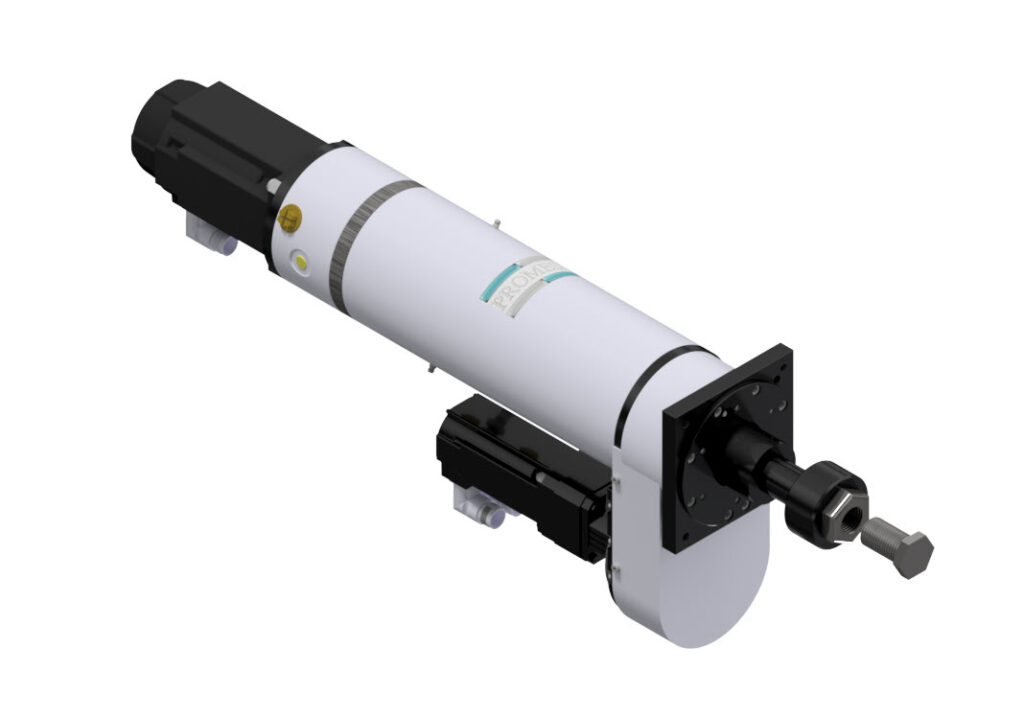

To resolve these issues, Promess implemented a closed-loop press and torque system using the REMAP (Rotational Electro-Mechanical Assembly Press) and UltraPRO Controller. The solution was seamlessly retrofitted into the manufacturer’s existing station with minimal modifications.

Here’s how the Promess system improved the assembly process:

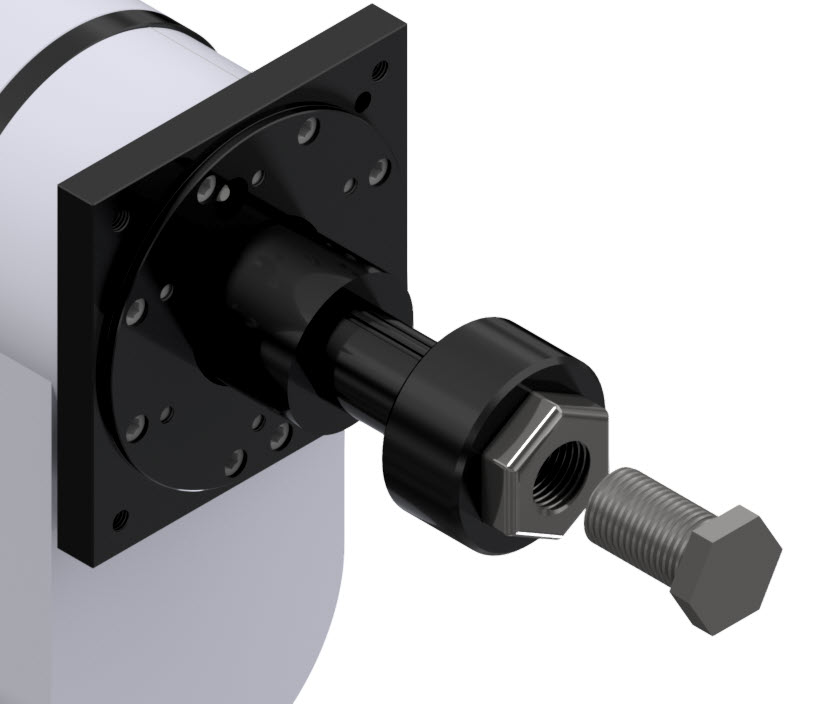

- Controlled Pressing & Positioning: The press gently applied 100 lbs of force, instead of slamming the parts together, ensuring precise engagement without thread damage.

- Smart Thread Engagement Detection: The torque axis rotated counterclockwise while the press monitored force-over-rotation data to detect the lowest point of force, indicating the exact position where the threads aligned.

- Intelligent Threading Process: Once the optimal position was identified, the system rotated in the correct direction, threading the parts smoothly before applying the final torque specification.

- Real-Time Data Monitoring: The closed-loop system ensured consistent engagement with full process traceability, eliminating the risk of undetected defects.

RESULTS

The Promess solution delivered immediate and measurable improvements:

- Scrap Rate Reduced by Over 80%: Defective parts were nearly eliminated, saving the manufacturer tens of thousands of dollars annually.

- Leak Test Failures Nearly Eliminated: With proper thread engagement, leak test failures dropped to almost zero.

- Rapid Return on Investment: The system paid for itself within 9 months due to reduced scrap and improved efficiency.

- Cycle Time Reduced by 10 Seconds: The process became faster and more reliable, increasing production throughput.

- Scalability & Expansion: Due to the success of the first implementation, the manufacturer expanded the Promess solution to three additional assembly lines, with the second system already in place.

By integrating smart sensing and motion control, Promess transformed the customer’s assembly process—eliminating thread damage, reducing failures, and cutting costs. Having advanced closed-loop control solutions can drive efficiency and quality improvements in manufacturing, ensuring reliable, defect-free assemblies every time.