Case Study #1635 | TORQUEPRO

Backlash Testing

Challenge

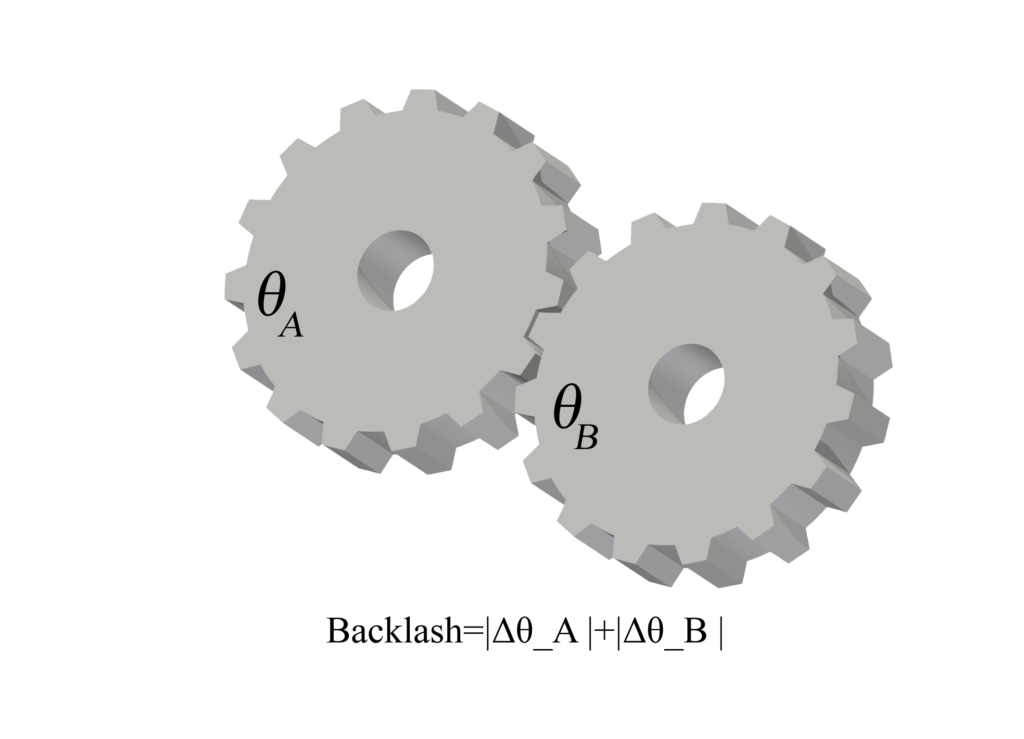

Measuring backlash is a critical test in almost all cases of gear manufacturing. A backlash specification is the criteria for how “loose” or “tight” a gear set is. Examples of too tight of backlash can create a jamming scenario under thermal expansion of the gears. Too loose backlash can result in the gears interfacing on a weaker part of the gear teeth.

In a typical gearbox assembly operation, backlash is measured when an assembly is almost completed, where an operator can access the gearset and place measurement devices. These devices typically include a type of dial indicator and fixturing to be able to access hard to reach areas in a housing.

These types of manuals tests can be ok for environments where time or quality isn’t a huge concern. For most manufacturers though, introducing a manual operation such as this leaves a lot of room for human error. The exact locations and tolerances for backlash measurements are usually defined, but the accuracy of a dial indicator is only as good as the operator placing the tooling and fixturing and recording the readings.

SOLUTION

Backlash testing can be separated into two methods: static, and dynamic. When measuring static backlash, the output (final driving gear) is held in a fixed position and torque is then applied in both directions to the input (driving gear) position values are captured and at a specific torque. The difference of the captured position values becomes the static backlash at one gear mesh point. This process is then repeated in other locations, results are then captured, compared, and stored.

Dynamic backlash testing involves the gear assembly being rotated to incorporate all gear-tooth combinations. All position values are then captured, stored, and plotted in both directions. Each position value is then compared to the corresponding one in the other direction to find the largest significant difference, the smallest significant difference or potentially any other difference that is relevant to determine whether the assembly is functionally capable and meets the specifications set by the manufacturer.

The Promess TorquePRO is a complete closed-loop servo system that controls motion, complete with software, electronics, cables, and sensors.

Using the TorquePRO to perform the strategy described above is an advanced method that not only removes the human error from manual backlash testing process, but can improve the time it takes to run, record, and store data for these tests. Variances in upstream manufacturing processes can be witnessed and compared to “Master” or known-good parts and removed from the assembly process completely if any characteristics fail outside of process limits.

The TorquePRO has the potential to help enhance manufacturing and machining practices internal to the plant but will also greatly reduce the chances of shipping a suspect assembly to the end-user.