In the fast-paced world of manufacturing, precision and quality assurance are paramount. Every component must be meticulously assembled to ensure optimal performance and reliability. However, achieving this level of precision can be challenging, especially when dealing with complex assemblies and varying components.

Learn how using the Promess Monitoring System transformed the assembly process, overcoming intricate challenges and ensuring 100% accuracy.

The Challenge:

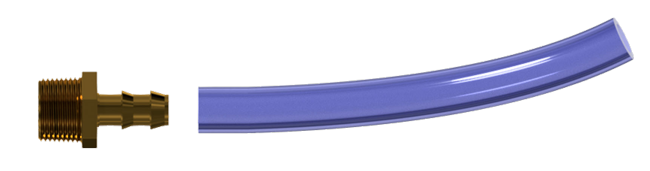

Imagine a scenario where a tube needs to be precisely fitted onto the end of a barbed fitting. Sounds straightforward, right? Not quite. In this case, there were three significant hurdles:

- Variable Sizes: The assembly line dealt with two sizes of tubes and two different sizes of barbed fittings, adding complexity to the process.

- Alignment: Achieving perfect alignment between the tube and fitting was crucial. Misalignment could result in irreparable damage to the tube during the assembly process.

- Depth of Pressing: The tube had to be pressed to full depth to ensure all barbs were engaged. Failure to do so could lead to the tube coming apart during application, causing potential issues down the line.

The Solution:

Enter the Promess Monitoring System. This innovative system revolutionized the assembly monitoring process by measuring the force exerted over a specific distance during assembly. By doing so, it could detect potential errors in real-time, addressing all three challenges simultaneously.

The Promess Monitoring System captured every detail of the assembly process, ensuring that each component was fitted with precision and accuracy. Any deviations from the expected force-distance signature were flagged, allowing for immediate intervention and correction.

The Outcome:

The implementation of the Promess Monitoring System yielded remarkable results. Not only did it streamline the assembly process, but it also exceeded the customer’s expectations. The system captured 100% of errors outside the taught signature, ensuring unparalleled accuracy and reliability.

Furthermore, the Promess Monitoring System provided certifiable documentation through Promess Data Acquisition, offering transparency and accountability throughout the assembly process.

In the ever-evolving landscape of manufacturing, innovation is key to staying ahead of the curve. The Promess Monitoring System exemplifies this ethos, offering a comprehensive solution to the complex challenges of assembly monitoring.By harnessing the power of real-time monitoring and data acquisition, manufacturers can achieve unparalleled levels of precision and quality assurance. This case study serves as a testament to the transformative impact of innovative technology in the manufacturing industry.

Are you ready to revolutionize your assembly process? Explore the possibilities with Promess Monitoring System and unlock new levels of efficiency and accuracy in your operations.