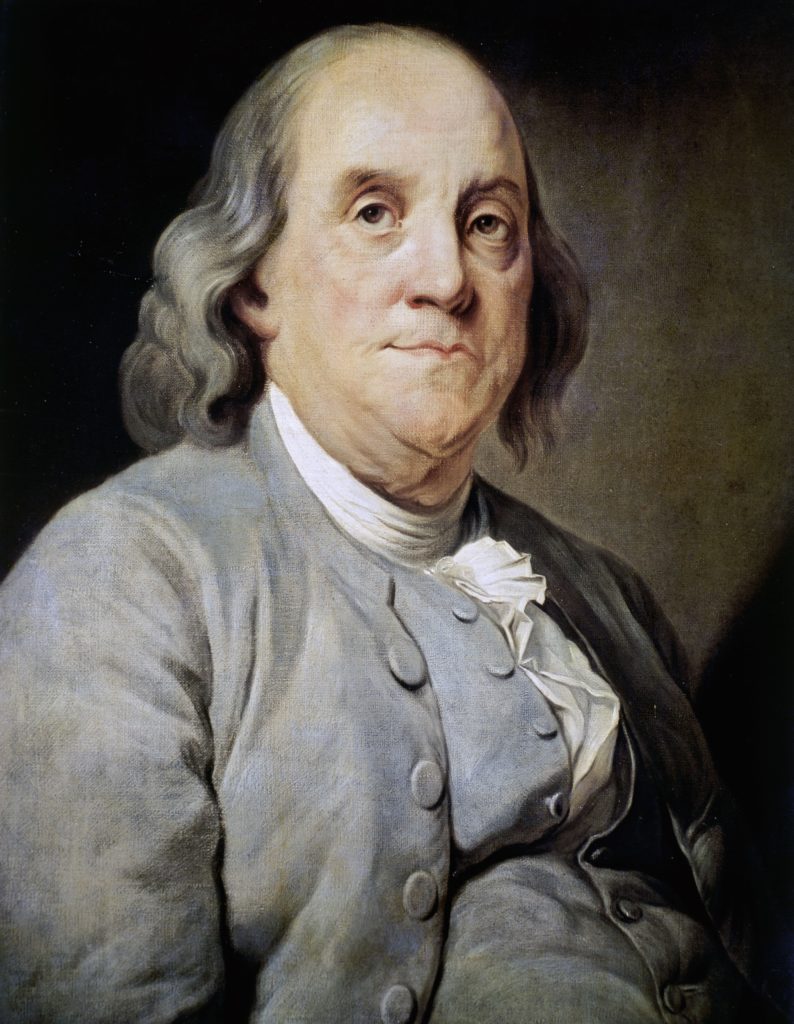

You’ve probably seen Benjamin Franklin’s saying “The Bitterness of Poor Quality Remains Long After the Sweetness of Low Price is Forgotten” more than once. It endures because it is as true today as it was when he said it a couple of centuries ago. And nowhere is it more applicable than in the decision to purchase capital equipment. Promess supplies our customers with systems built around the Electro Mechanical Assembly Press (EMAP) technology we pioneered more than three decades ago. Our presses are built in-house using components either manufactured by us, or produced to our exact specifications. Every component part and every press is built with the industry’s largest safety factor and de-signed to provide reliable operation for decades or longer with minimal maintenance. Size for size, an EMAP is nearly always heavier than competitive units and costs more to purchase.

So why has Promess sold thousands of EMAP based assembly systems? It is really quite simple, Promess products provide the industry’s lowest Total Cost of Ownership. Ben Franklin knew the importance of this, and so do the Promess customers who bought these systems.

Total Cost of Ownership Costs

- Up front cost/calculated lifetime in years = cost per year

- Operating cost – a Promess system only consumes power when it is performing useful work

- Floorspace – a Promess system requires no supporting equipment like hydraulic or pneumatic supplies including: pumps, hoses, filters, dryers, fluids, valves, or regulators

- Cost of on-site system setup – included with a Promess system

- Cost of on-site system training – included with a Promess system

- Cost of phone support – included with a Promess system

- Cost of planned maintenance downtime — 1 hour per year to grease and calibrate a Promess system

- Cost of unexpected downtime – a Promess system is more reliable – What does down-time cost your company?

- Cost of unexpected process changes for factors like part tolerance changes and unexpected part defects – simple program changes are easy and included with a Promess system

Intangible Consequences

And, then there are the more intangible consequences that frequently occur:

- When the technology is “oversold” and does not perform “as advertised”

- When the technology cannot support changes to the product or process

- When the technology is specified incorrectly and can’t support the application

- When service and support is not readily available or not available domestically

- When service and support providers do not have the experience or expertise to re-solve issues in a timely and cost-effective manner

- When you’re forced to carry an inventory of spare parts

- When runoff, shipment, pre-production and production start-up fail or are delayed

All of those consequences are possible and extremely common when the technology is selected solely based on the lowest purchase price.

Finally, looking ahead to the eventual end of production, will the system components simply be scrapped, or can they be re-purposed to reduce the capital cost of the new system? The answer to that depends on the quality and flexibility of the components.

Promess Electro-Mechanical Assembly Press (EMAP)

Promess EMAP-based systems are inherently versatile because the presses are completely pro-grammable, and they are built to last with robust components sized to withstand the rigors of industrial production. That is not likely to be true of many lightweight, lower-cost competitive products. That means the EMAP often can become part of a new process with a simple change of tooling and a new program, spreading its initial purchase cost over more than one project and more than one product cycle to slash the Total Cost of Ownership.

In the end, the Electro Mechanical Assembly Press (EMAP) is a piece of long-term capital equipment rather than a commodity with a limited life. Looked at from a Total Cost of Ownership perspective that means its higher initial purchase price is more than justified by its lower operating cost and exceptional Return On In-vestment potential.

It is true you can spend less, but it will almost certainly cost more in the long run.