When it comes to bringing a new product to market, or to doing re-design on an existing product, Product Lifecycle Management (PLM) is important to consider at every step along the way.

From the manufacturer’s standpoint, PLM consists of 4 essential elements: Conception, Design, Realization, & Continuous Improvement.

Partnering with Promess helps you at every step.

Product Conception

Product Conception starts with a need. Someone, an end-user or another manufacturer, has a need for a product that fulfils a function, maintains a certain level of quality, and can be obtained at a reasonable price point. Promess’ team has a tremendous amount of experience helping their customers take their products from concept to reality.

Product Design

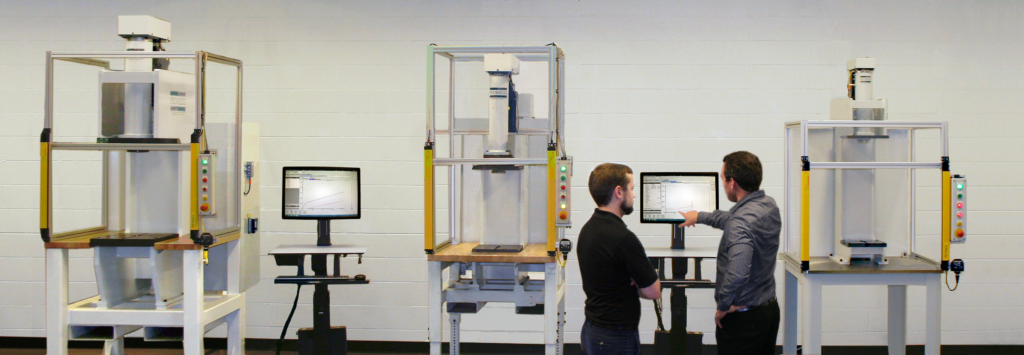

The Promess Process Development Center (PDC), located in Brighton MI, can help you assess your unique parameters, including force & torque requirements, as well as the best processes and equipment to further ensure your success. While we are neither a design-house nor is the PDC a test lab in the typical sense, our team of applications engineers will bring their expertise to your process from its very conception.

The Design of your product must take into account dozens of factors, at least, including usability & function, of course, but also ease of production. Testing your parts manufacturability in The Promess PDC gives you great insight into the feasibility of efficiently manufacturing and testing the product you are bringing to market, whatever that may be.

Realization of Product &Process

Once you have a product defined & designed, as well as a process (in place or visualized) to manufacture it, the next step is Realization of that product and process. Promess, with their lines of EMAP, REMAP, TorquePRO & Work Stations, are uniquely capable of helping you make this transition. The same Work Stations that are used in the PDC are available as plug-and-play solutions for your shop floor. Whether you use a Work Station that requires little more than power applied to be up-and-running on your shop floor, or you use systems integrated into your new and existing assembly stations, Promess makes the journey from design & test, to production, almost seamless.

And finally, the journey does not end just because you are successfully producing quality products on your shop floor.

Continuous Product Improvements

As the Promess system does its job, its integrated sensors and in-process monitoring & gauging, give you a tremendous amount of data which can be used not only to verify individual assemblies & processes, but which can be put to use for continuous improvement efforts to improve your product AND make your processes more efficient. Over time, costs go down and customer satisfaction goes up. What could be more worthwhile than that?

As with all things, eventually, a product’s lifecycle comes to an end. Promess, with its insistence on high quality and durability, provides systems that are capable of outlasting even the products they produce. These systems are rugged enough AND flexible enough, that they often become essential tools in the design and production of “what-comes-next,” as well.

When you work with Promess, you do not just get a piece of equipment. When you work with Promess, Promess works with you, bringing a tremendous amount of experience and expertise to help you succeed at every stage in your Product’s Life Cycle. When Promess works with you, you increase your likelihood for customer satisfaction, and ultimately, your own success as well.