Promess’ EMAP System comes with an intuitive and easy-to-use HMI that is consistent with the ideals put forth in Industry 4.0.

Industry 4.0 emphasizes, among many other things, the Visual Factory Floor. When many of us think of the Visual Factory Floor, we think of markings on the floor showing where things belong – so we know when they are NOT there – and labels showing how much of what should be where to minimize second guessing.

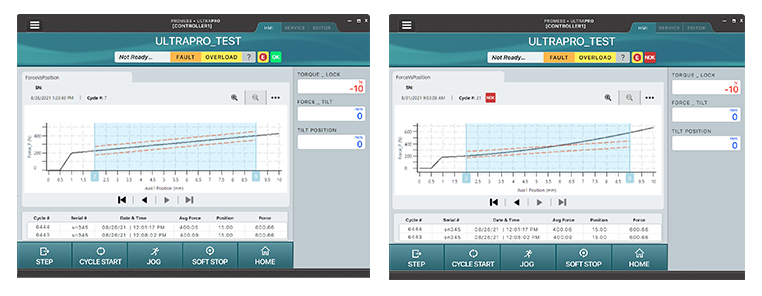

The Visual Factory Floor paradigm does do those things, but when implemented correctly, it can do much more. The HMI of Promess’ Assembly Press Systems takes the Visual Factory Floor to the next level, providing immediate and accurate visualized data that verifies each assembly, as it is produced. The HMI can be set up to show several different datapoints of interest including the total number of parts run, as well as the number of failed parts.

Additionally, the HMI displays the system status so you know, in real time, the state of the machine – running, faulted, editing, etc. – which can be very helpful for troubleshooting and avoiding potential problems. Knowing quickly, with readily understood data displayed, precisely what has occurred in the assembly process, ensures everything has been done properly. In the event that something does go wrong, the Promess System will know it, and let you and your operators know it too, allowing it to be corrected that much more quickly so you don’t lose valuable time in your effort to produce the best components for you and your customers.