In the intricate world of automotive manufacturing, even the smallest components play a critical role in ensuring vehicle performance and safety. Among these components, power steering pump pulleys hold a pivotal position, demanding precise assembly to guarantee optimal functionality without compromising internal components’ integrity.

Meeting the Challenge:

For a manufacturer tasked with assembling power steering pump pulleys onto shafts, the challenge was twofold: achieving precise alignment relative to multiple mounting flanges on the pump housing while accommodating different pump models with quick changeover capabilities. Additionally, the assembly process had to ensure an average position based on readings from three external transducers.

A Tailored Solution:

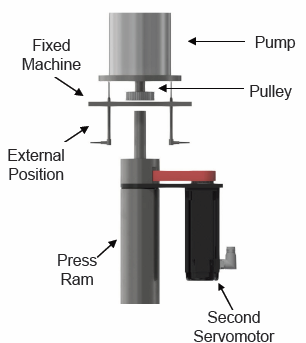

Enter the Promess Electro-Mechanical Assembly Press (EMAP) – a game-changer in the realm of precision assembly. With its EMAP-20 model boasting a 4,500 lbs. capacity, the manufacturer found the ideal solution to their complex assembly requirements. Integrated with a second servo motor provided by Promess and three external position transducers, the EMAP system offered a comprehensive solution for precise assembly operations.

How It Works:

Using the Promess software’s advanced features, including the Master function, the assembly process was meticulously calibrated to ensure consistent and accurate results. A master part served as the benchmark, enabling the calibration of the position transducers to establish the zero position. During assembly, the system dynamically adjusted the press depth based on measurements from the transducers, ensuring that the pulley was assembled to tight tolerances without causing damage to internal components.

The Outcome:

The implementation of the Promess EMAP system yielded remarkable results, transforming the power steering pump assembly process. With assembly tolerances of ± 0.05mm or better achieved, the system surpassed the stringent requirements of different pump models. Setup time was dramatically reduced to just 30 minutes, enhancing overall productivity and efficiency on the shop floor.

Moreover, the EMAP system offered unparalleled flexibility, allowing for seamless integration with various pump models and quick changeover capabilities. By ensuring precise assembly without compromising internal components’ integrity, the system contributed to the production of high-quality power steering pumps, meeting automotive industry standards and exceeding customer expectations.

In the dynamic landscape of automotive manufacturing, precision assembly is not just a goal; it’s a necessity. With the Promess EMAP system, manufacturers can elevate their assembly processes to new heights of accuracy, efficiency, and reliability. As demonstrated in the case of power steering pump