On the shop floor, space comes at a premium. Every square meter of floor space MUST be put to its most productive use. Oftentimes, shop floors are set up to have components being assembled moved from station to station for each operation applied to them.

Where space is a factor, or where it makes more sense to have multiple operations performed while the part is in the same space, there are better options available. Among the best shop-floor-ready options for maximizing productivity in limited work spaces, are Promess’ Robot and Gantry Presses.

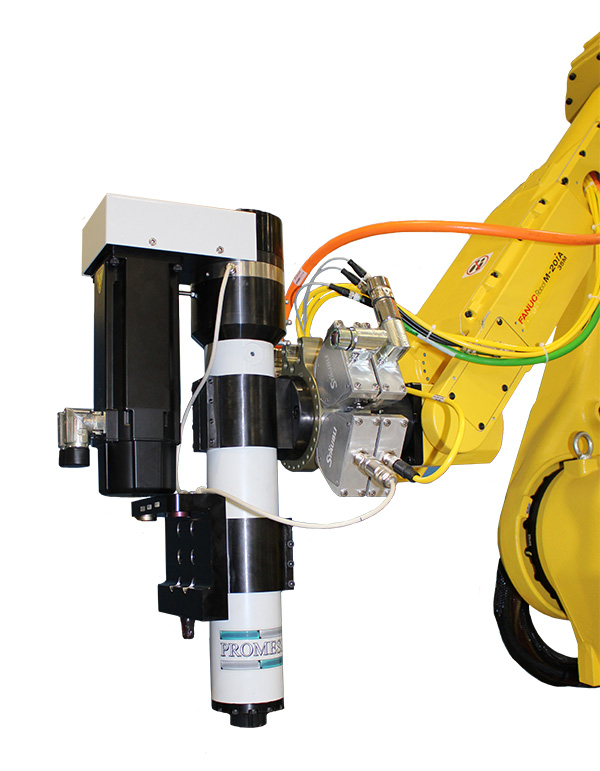

The fully electric, lighter-weight Robot Press with its mountable housing is intended for use in flexible assembly cells where the process requires that the press be brought to the part rather than bringing the part to the press.

The Robot Press is designed to be affixed to a multi-axis robotic arm, in conjunction with a backstop, to provide maximum efficiency at a significantly lower cost than would be incurred by multiple presses in multiple stations. Part changes or adjustments can be made by changing robotic positioning rather than swapping expensive tooling and die sets or changing machine designs.

The Gantry Press System incorporates an EMAP (Electro-Mechanical Assembly Press) into a Gantry Style Workstation so that press can be positioned anywhere in the XY plane in order to perform multiple press operations within the same work envelope without the need for multiple presses.

This eliminates the complications of working in too small an area, and can save a tremendous amount on capital equipment while providing accurate, gaged press-fits that ensure quality for your customers.

To learn more about how to maximize productivity in restrictive work envelopes, contact Promess at [email protected] or call 810-229-9334.