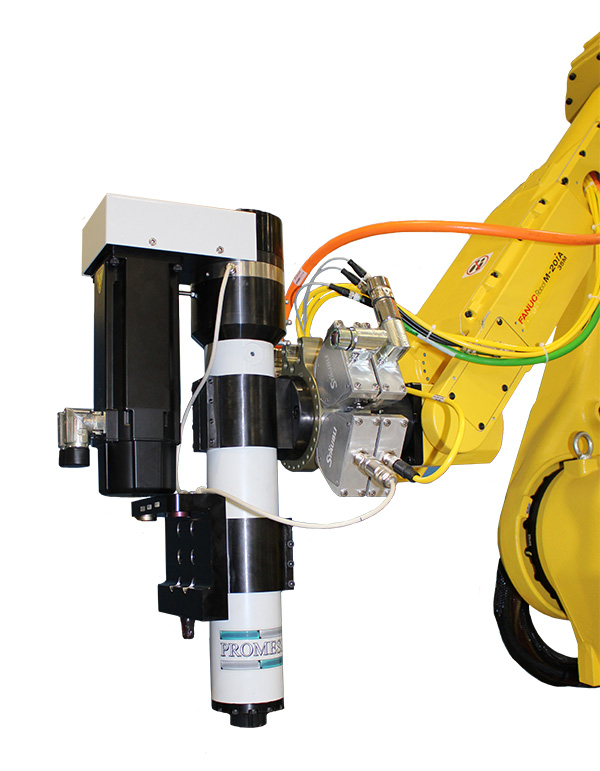

Promess Inc. is keenly aware that even the newest, latest & greatest products on the market benefit from continuous improvement, especially when that improvement is driven by customer feedback. With that in mind, Promess is releasing a new quick connect / disconnect feature on the Promess Robot Press.

Quick Connect / Disconnect Feature

The new quick connect / disconnect feature allows one robot to handle multiple operations, because the robot isn’t tied to only the press. Now one robot can be used to pick up the press, as well as other end effectors (grippers for material handling, Promess’ TorquePRO, etc.). This reduces the total number of robots needed in cell, greatly reducing cost.

Mechanics

The Robot Press is a lightweight press system intended for use as end effectors in robotic assembly applications and is available in sizes up to 50 kN offering a 200 mm stroke and 300 mm/sec speed. The Robot Press also feature a lubrication system that allows automatic greasing of the ball nut. The press design reduces system downtime for lubrication from minutes to seconds and facilitating completely automatic greasing cycles.

The Robot Press features a lubrication system that allows automatic greasing of the ball nut. This significantly reduces downtime for lubrication and facilitates completely automated greasing cycles. The Robot Press still features second-generation servomotors that provide increased torque in a smaller frame size, further reducing their weight. They are equipped with absolute encoders for position sensing and do not require proximity switches. Only three cables are required between the press and the controller: one for the load cell, one for motor power and a third for position feedback.

Application

Promess Robot Presses are intended for use in flexible assembly cells where the process requires that the press be brought to the part rather than bringing the part to the press and the latest updates to the design provide an unparalleled level of flexibility to meet all your assembly and testing needs. In operation, the Robot Press is brought to the part by the robot and the tooling is engaged. Press motion is fully programmable, and presses are equipped with force and position sensors to support intelligent assembly operations.