It’s been a challenging year for manufacturing. Promess Inc. has been busy moving into a new manufacturing space and boosting inventory to keep lead times low. As ever, Promess remains committed to providing the highest quality and most innovative servo-based manufacturing and test systems. This year at Automate, Promess will be featuring a variety of new and proven systems, including: EMAP, Benchtop Workstation, Gantry Workstation, Robot Bridge, and Machine Tending with Promess’ Indexer Workstation.

Free registration is currently open to attend the Automate Show in Detroit, Michigan June 6-9, 2022. Promess will be exhibiting at Booth 4303.

Electro-Mechanical Assembly Press (EMAP)

The EMAP, or Electro-Mechanical Assembly Press, is a fully electric, servo-based press system with intuitive and flexible software allowing for maximum utility. The highly accurate EMAP is available in a range of sizes form .2kN up to 1MN, and standard stroke lengths up to 660mm (with additional customization and longer custom stroke lengths possible). Even as is, these systems are highly accurate and precise, and can be made even more so to achieve whatever accuracy & repeatability is required for both force and position.

Benchtop Work Station

The Benchtop Workstation is a lighter-weight, compact, plug-and-play Workstation capable of supporting EMAP presses up to 20kN with the same precision, ease-of-programming, and integrated safety as the full-sized Workstation.

Gantry Work Station

The Gantry Workstation frees you from the limits of a rigid, stationary press by combining all the advantages of the standard Workstation with a gantry that allows the press to be accurately positioned anywhere within the Workstation’s work envelope. That’s 600mm x 600mm of x/y movement for the size 1 Gantry! And the gantry allows the press to be moved part to part as your need dictates.

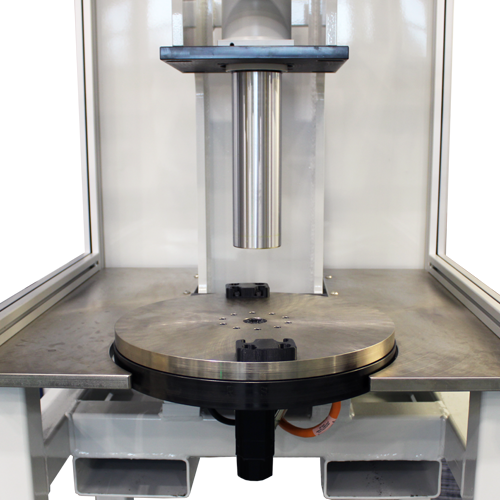

Index Table

And the Indexer Workstation facilitates seamless Machine Tending (robotic loading & unloading), and manual loading & unloading, for the greatest productivity and throughput while still delivering the highest quality, assembled & tested products, complete with data for verification (and process validation).

The Robot Bridge combines an EMAP’s precision for force and relative motion, with a robot’s flexibility for positioning and pressing multiple points within a small workspace.

It’s been a difficult time for manufacturers around the world, but soon, the world will be back to normal, and just as they’ve been throughout, Promess will be there to help you succeed, with US-based manufacturing, 24/7/365 service & support, and representation worldwide. While most have just been trying to keep up through, and survive the difficulties faced by manufacturers these last couple years, Promess Inc. continues to innovate and focus on what’s next.

Make sure to check out the Trade Shows Promess will be exhibiting at this year!