Are you looking to understand and improve your manufacturing process? If so, it may be time to upgrade to a smart system.

Assembly monitoring helps you identify bad parts, in-process by detecting over-force, misalignment and more. In-Process Monitoring provides you with data trends to improve your manufacturing process, make changes on the fly and it gives you full visibility into precisely what is occurring during every step of your process.

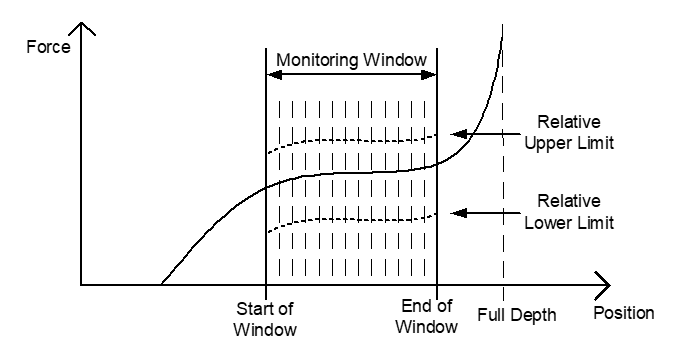

With a smart system, the software provides a monitoring window displaying a curve with each assembly.

The Graph

Promess press-fit monitoring software is used to generate a Force vs. Position graph and real-time feedback which can be used to determine a good or bad assembly.

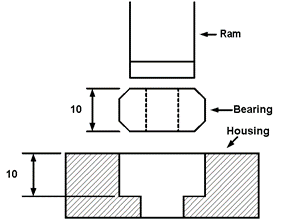

The Process: Pressing Two-Component Assembly

Components are pressed together to either to a position or a specified force. During the process, the Promess software collects force and position values.

These values are used to create a force vs position curve. The curve is monitored within an adjustable window, which allows the user to define the critical part or “Area of Interest” of the assembly cycle. During this critical portion of the assembly operation, the force level is closely monitored. If the force level crosses an upper or lower limit the part will be flagged as “bad.”

The full-depth position is also monitored to be within an adjustable tolerance.

Applying a Press-fit Monitoring Strategy to Force vs Position

The Promess press-fit monitoring strategy is a very effective method of ensuring the proper assembly of two components. Every press-fit application may need a slightly different monitoring approach.

If you have any questions, please feel free to call Promess at (810) 229-9334 to discuss your application with one of our engineers.