“Quality” has been the holy grail of manufacturing for more than 40 years. It’s a worthy goal. High quality leads to satisfied customers, higher productivity and, if done right, lower costs and higher profits.

But, if it’s not done right quality can come at a very high price. In the assembly arena the key to “doing it right” often requires a reappraisal of just what “quality” really means to a customer.

For example, does your customer really care about the precision with which all of the components in an assembly were manufactured? Or is It more likely that their real concern is how well the assembly functions in their product.

You may be wasting money at the sub-component level when the real quality is determined when the parts are assembled. What if you could assembly the part while measuring it’s functionality in real time, adjusting for small inconsistencies in sub-components, making an assembly that functions perfectly every time.

Ball Joint Assembly

Ball joints are an excellent example of what can be accomplished by this approach. Millions of them are made annually for thousands of applications and none of the end users care anything about how precisely the component parts were made.

What those customers want is a ball joint with low lash that articulates with the specified amount of resistance. Meeting that expectation is a function of the fit between the ball and cup of the ball joint and that fit is determined at the time of assembly.

The traditional approach to ball joint assembly requires a precisely manufactured ball and cup that are then crimped together to a fixed dimension. The result is an unnecessarily costly product that may, or may not, pass a post-assembly articulation test to verify compliance with the specification.

But the specification is functional and not dimensional, so the same result can be accomplished with less precise components and a more intelligent assembly process. So instead of crimping to a fixed dimension and hoping to get a good assembly, an intelligent process will crimp until the desired articulation force is reached and then stop. The key is to measure function in real time during the assembly process and not dimensions.

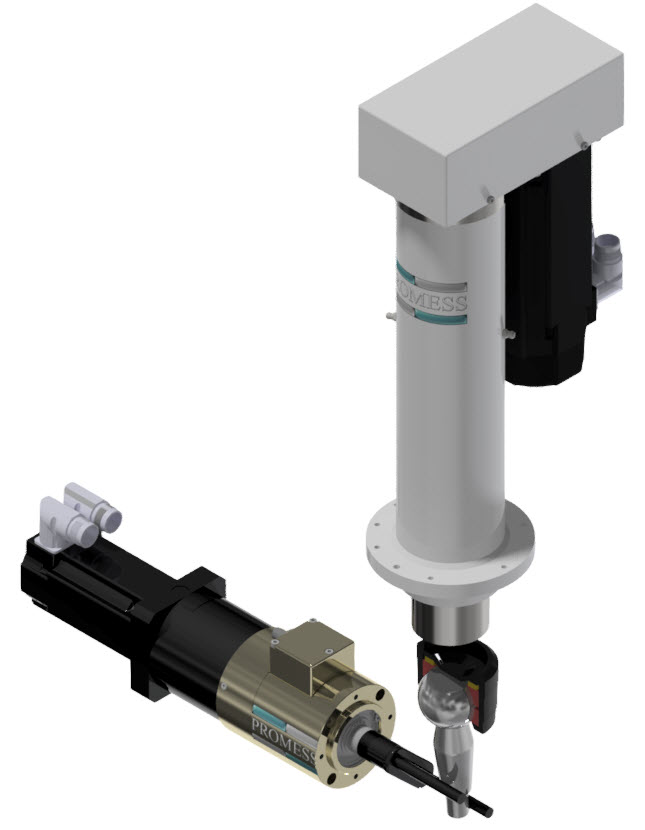

This can be done using a combination of Promess’ Servo Press (EMAP) and TorquePRO technologies controlled by a Promess UltraPRO Multi-Axis controller. Here’s how it works in a real world application.

Assembling to a Functional Specification

Components are loaded into the machine either manually or automatically and the Promess UltraPRO Controller moves/directs the press ram down to find the initial engagement point (touchpoint position) on the cup; gauging this initial height. This allows the system to negate the variances inherent in the component heights. The servo press then extends an additional distance to begin forming the crimp that retains the ball.

The UltraPRO controller then commands the TorquePRO unit to articulate the ball through a pre-programmed set of angles while measuring and capturing the torque required for each motion. This process is repeated as the press ram continues to form the crimp providing realtime feedback on the function of the assembly. Each torque measurement is checked to see if they fall within acceptable tolerances.

While articulation torque is too low, the crimp is too loose and the EMAP will cycle again. But it now moves to a preset force value instead of a position value while the TorquePRO continues to test articulation torque.

This Press-Measure-Press cycle is repeated until the measured articulation torque is optimal, ensuring that every Ball Joint assembly meets the same functional criteria every time. Once the assembly is processed to the optimal articulation torque level the TorquePRO system can run a short ‘wear-in’ routine exercising the assembly through several “Full Range of Motion” cycles, where the performance data is tested again and stored for future reference.

This method calibrates a perfect assembly every time even when using less precise, and herefore lower cost, components. “Wear-in” and “Full Range of Motion” testing are added benefits and all of the data generated in the process can be stored for subsequent analysis.

Intelligent assembly processes can help you make better products while lowering component costs and eliminating the need for post process testing stations. It’s a genuine win-win solution for you and your customers.