Since Promess introduced its first electric servo-controlled press system in 1991, the success of this technology in intelligent assembly and test systems has spawned a number of competitive products in the market. When there was only one product to consider, the choice was easy. Today, it is a bit more complicated.

There are three basic aspects to consider when evaluating the true value of an electric press system in any manufacturing application: mechanics, controls/software, and support. Here are some of the things to look for in each category.

Mechanics

The system needs to be robust enough to survive in the production environment and there are some specific component characteristics that are critical to ensure this happens.

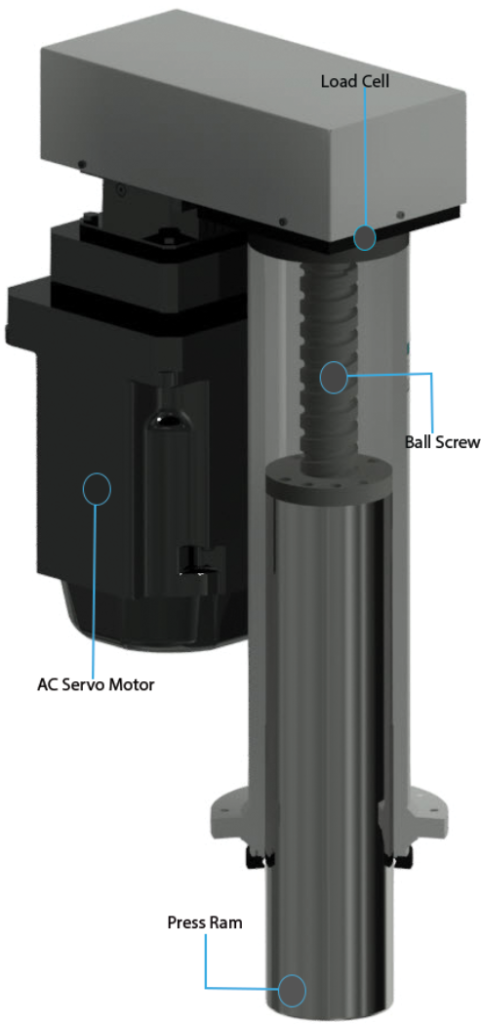

Press Heads

The weight of commonly available electric presses varies by as much as 400-percent. This is where the “rubber meets the road” in a press and heavier is definitely better. Light weight presses may be less expensive to produce, however they tend to cost much more down the road with downtime and maintenance concerns.

Ballscrews

An electric press is not a “standard” application for a standard ball screw and commercial ballscrews are not engineered for these operating conditions either. The most cost-effective, long-term solution is a custom-engineered ballscrew.

Sizing is also an important consideration. The absolute minimum size for a electric press ballscrew should be 2.5 x dynamic load to rated capacity.

Motors

To achieve maximum service life motors should be sized to run in the continuous current range over the full range of the press rather than requiring peak current at some points.

Gearing

Lower gear ratios reduce motor fatigue by lowering the ratio of servo RPM to spindle RPM. Lower RPM is better. It is also quieter.

System Sensors

Force sensors, typically strain-gauge load cells, should be physically integrated into the press head assembly to provide maximum protection.

Position sensing is typically accomplished via the servo motor encoder. It is important that the encoder provide sufficient accuracy and repeatability to meet application requirements.

Other Important Features

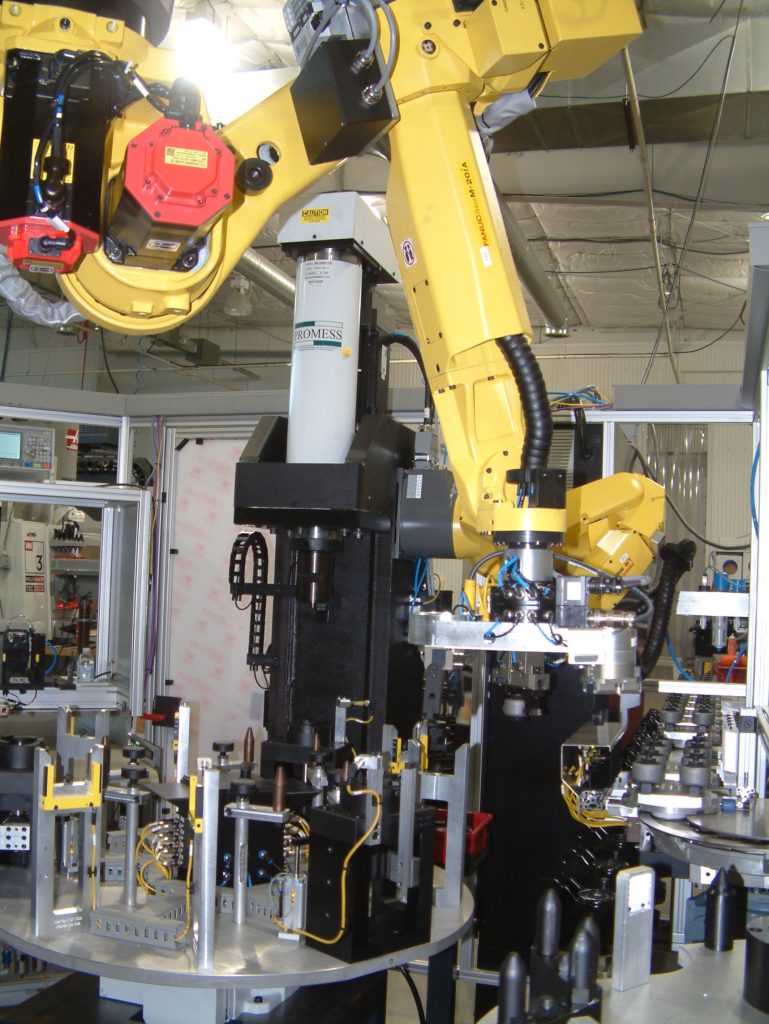

- Ability to perform in compression and tension and in any orientation.

- Ability to run at rated capacity for any duty cycle.

- Ability to move to and hold a specific force indefinitely without a brake and without damaging the motor, gearing, sensors or ballscrew.

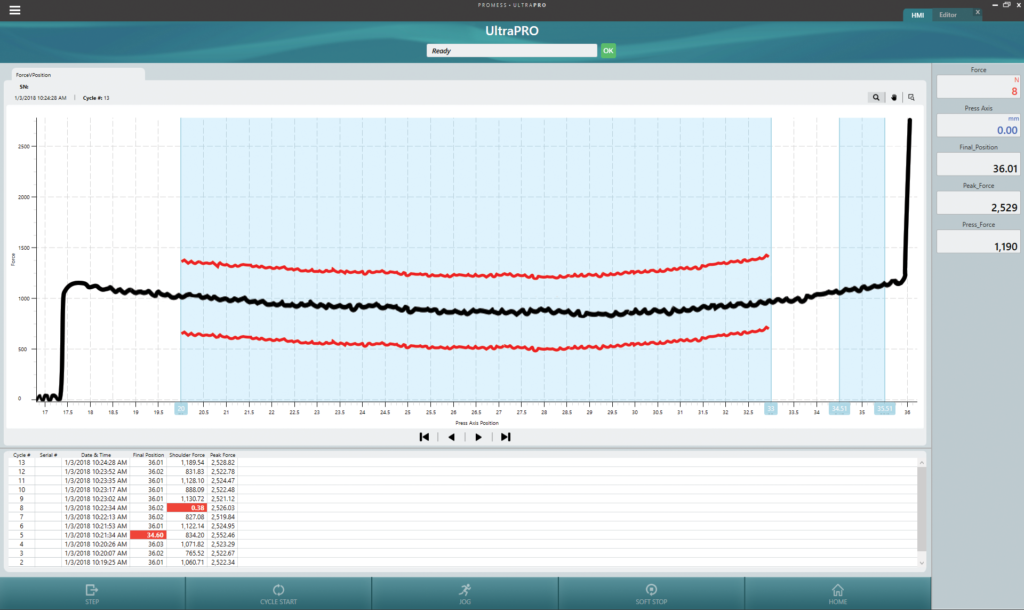

Controls/Software

Motion control and monitoring functions should be integrated as much as possible to simplify system configuration, support upgrades and changes, and provide the maximum amount of flexibility and re-configurability. Some of the more common requirements are listed below.

Important Motion Control Capabilities

- Press to an external dimension which should includethe ability to interface with external digital probes

- Move to a rate of change function

- Applied velocity

- Applied torque

- Closed loop torque control

- A command language to create custom command routines

Important Software Data Analysis Functions

- Curve math

- X &Y crossing

- Global macros & variables

- Global variables

- Monitoring over steps

- Dy/Dx function

- Local macros

- Live expressions

- Monitoring over macros

- Gaging minimum, maximum, average over steps and macros

- A full math engine with an expression language(so you can create your own evaluation commands)

In general, the more of these capabilities that are available in a standard unit, the more capable and flexible it will be.

Service and support are essential, and all of the standard evaluation criteria apply. Talk to users with similar applications if at all possible rather than depending entirely on the supplier’s statements.

Application engineering experience and technical support resources are of particular importance. A good track record in real-world applications is an essential starting point, and a bad one should at least be a red flag and probably a deal-killer.

Finally, a focus on the long-term Total Cost of Ownership rather than initial capital cost will pay large dividends. Electric Presses are not “throw-away” items. The ability to reconfigure them for future applications should be an important consideration in the selection process.

If you want to learn more about electric presses, click here.

For more information contact Promess at 810-229-9334 or [email protected]