One of the newest trends in the arena of manufacturing is cellular manufacturing.

Traditional assembly line manufacturing had operators perform their individual tasks, exactly as prescribed, over and over again, as the unit being assembled came past on a conveyor or was brought to them by some such similar means. Assemblies would be passed through areas where, for example, multiple machining operations might occur, then on to multiple pressing operations, then welding, etc. This was a great way to utilize lower-skilled operators to consistently produce identical, or nearly identical, high quality parts and products. There is no doubt that assembly line manufacturing has served us well in the past, and in many instances, will continue to do so going forward.

Many, however, are now looking toward Cellular Manufacturing as the future.

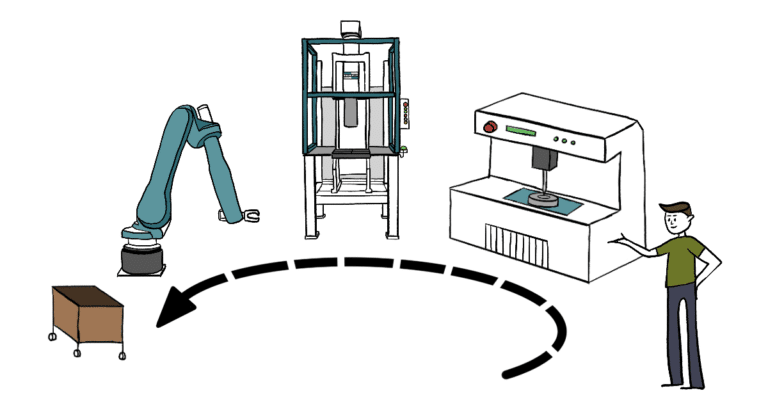

The idea behind cellular manufacturing is that many different processes for similar components/products be performed in a single cell. Operators in these cells are given more autonomy to innovate, solve problems and implement solutions, contributing to continuous improvement and raising productivity, product quality, worker satisfaction, and various other factors. The more immediate, easily-visualized data these operators have, the more effectively they can perform and make improvements over time.

That’s just one of the areas in which Promess’ systems for applying & measuring force & torque, as well as positioning, is an ideal solution to bring to your cellular manufacturing processes.

Promess systems are capable of

- accurate monitoring of force & torque

- programmable control of force & torque

- precise & repeatable linear & rotational positioning.

As a result, operators who are using Promess technology, whether for assembly or for testing, get immediate and easily visualized data, and can react to such in real time.

The Promess system on its own, is capable of being programmed to stop, re-run an assembly, or merely tag the assembly as out of spec, and proceed with further assembly. Introducing Promess’ in-process monitoring and gaging in the cellular manufacturing environment, allows those decisions re: how to proceed for any individual assembly, to be made by a thinking, breathing human being.

It also allows for immediate operator intervention to prevent the issue from recurring and gives the operators involved the data they need to contribute to continuous improvement and innovation that will make your operation more efficient and allow you to supply your customers with the highest possible quality products.

Time will tell if cellular manufacturing truly is the future of assembly, but if it persists, you can be sure that Promess will be part of what makes cellular manufacturing a more practical and implementable solution on your shop floor.