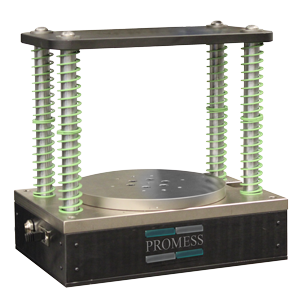

Promess, Inc. has introduced the Smart Press Frame, a force/position measurement system that electronically digitizes operations performed by manual or hydraulic and pneumatic presses. Available with 8”x 8”, 13”x 13” and 18” x 18” working areas and capacities of 1,3,6 and 12 kN the Smart Press Frame is a standardized solution for process development, quality verification, R&D and low-volume production applications across a broad range of industries.

The Promess Smart Press Frame offers users an alternative to costly, ad-hoc “science project” press measurement solutions often seen in R&D and process development labs. It also provides a cost-effective way to add in-process quality monitoring and traceability to low-volume assembly operations. Adding that capability can eliminate the need for manual post-process inspections and detect upstream part issues.

“The Smart Press Frame is modeled on a standard die set,” explained Andy Joseph, Promess Director of Product Development. “It has a base and an upper platen that moves on guides as the press force is applied. What makes it unique is the load cell and position sensor installed in the base that monitor and record the force/position relationship throughout the press stroke.

“The resulting digital ‘signature’ of the operation can be used in a variety of different ways to support process development, research or quality assurance applications. Smart Press Frame units have been applied successfully in operations including bearing pressing in medical devices, installation of cup plugs in automotive valve bodies, and small batch production of developmental parts for electric vehicles.”

Data generated by the Smart Press Frame is fully compatible with other Promess systems based on their Electro-Mechanical Assembly Press (EMAP). That means prototype processes developed using the Smart Press Frame can be migrated to EMAP-based production systems with high confidence of success.

“In many cases,” Joseph added, “processes developed on laboratory equipment don’t translate directly to production systems. It’s not uncommon for a significant amount of ‘just in case’ capability to be specified for the production equipment which drives up the cost. With good data that’s simply not necessary and the savings can be substantial”.

Promess is a 35-year-old firm that develops, manufactures, and markets its family of sensing devices, electronics, assembly presses and test systems on a global basis.