ULTRAPRO MONITORING

Promess Method

The Promess UltraPRO Monitoring System allows for the in-process monitoring of your assembly and test operations.

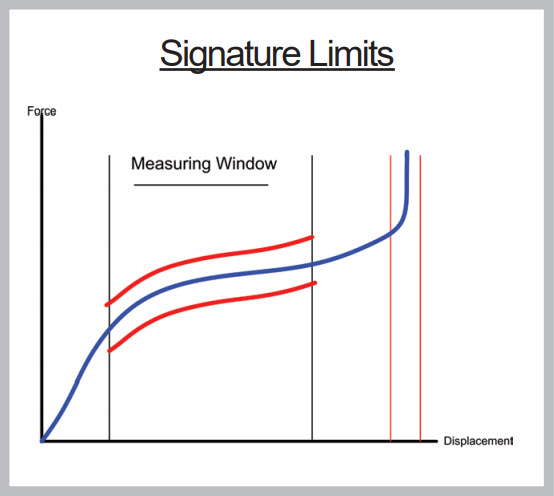

The Promess Monitoring System will collect, graph and store the force vs. position signature curve for the process being monitored. The system also allows for upper and lower limits to be placed around the process signature to detect a good or bad part.

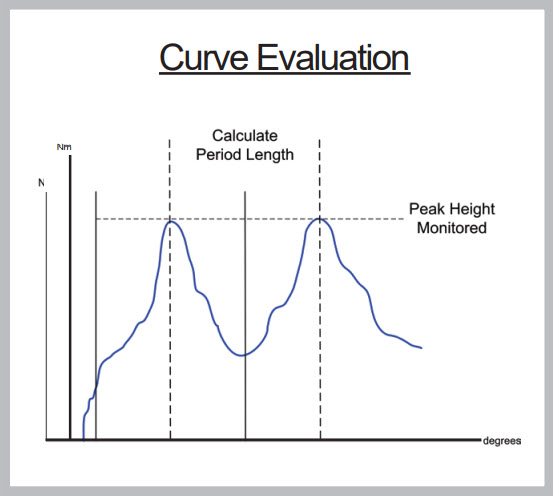

Other functions within the system allow for the gauging of defined features, like final position and force. Using the Expression function and other commands unique to the Promess software, the user can build algorithms and tests required for their application.

The Promess Monitoring Strategy can Detect

✔ Tight Fit

✔ Full Depth Exceeded

✔ Loose Fit

✔ Wrong Part

✔ No Part Present

✔ Part Misaligned

MONITORING APPLICATIONS

PRESS FIT

CRIMPING

RIVETING

TESTING

PROMESS ULTRAPRO MONITORING

Features & Benefits

- In-process, online quality verification

- Teachable high and low signature limits

- Advanced math functions

- High sampling rate

- Retrofittable to existing machines

- Backed by Promess Support 24/7/365

- Part traceability

Promess Provides

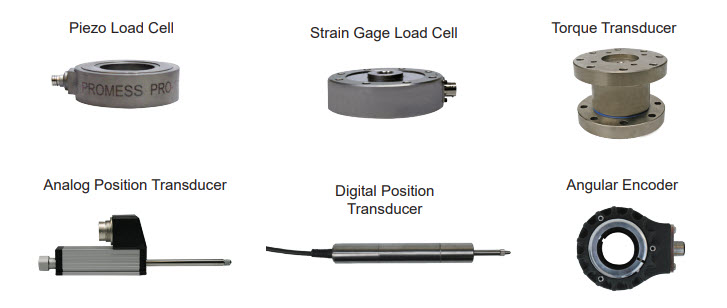

✔ Monitoring electronics

✔ Position transducer

✔ Training

✔ Force transducer

✔ Installation assistance

✔ Data acquisition

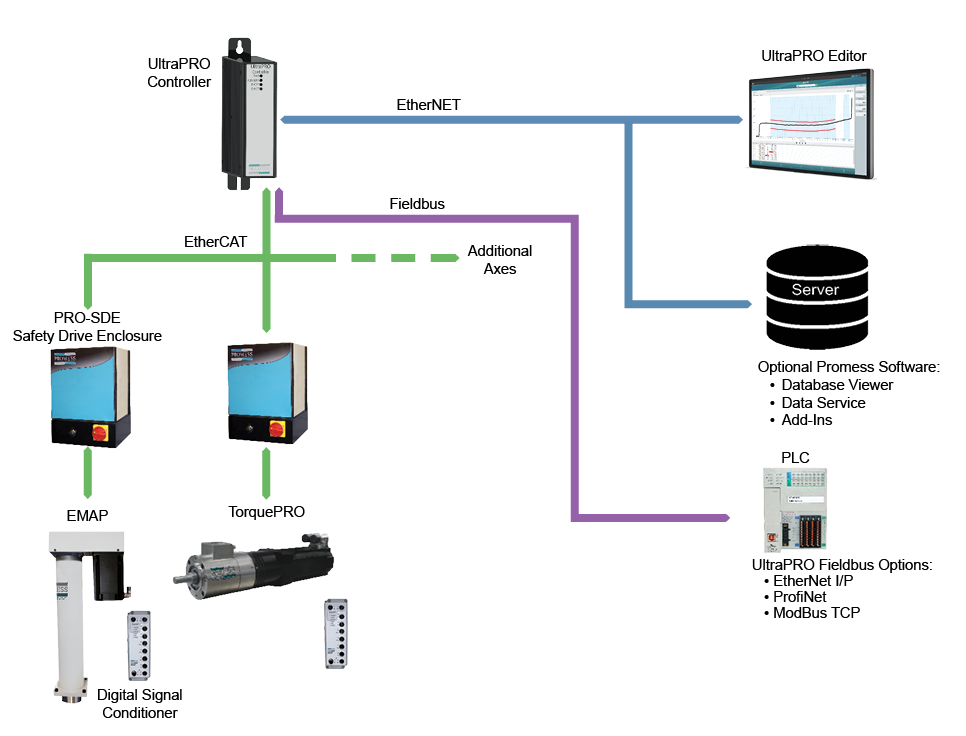

PROMESS ULTRAPRO SYSTEM