Press and Rotate Applications

REMAP Applications

Promess REMAP Application Systems are used by Builders and End Users in a broad range of testing, monitoring and assembly applications.

- Seal Press

- Bearing Pre-Load

- Spline Alignment and Press

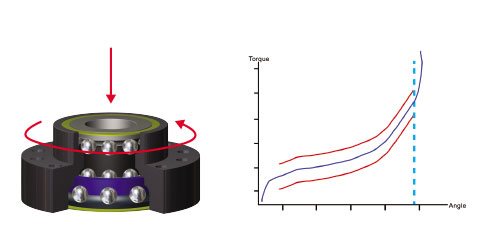

Application: Bearing Pre-load

The REMAP is the perfect tool when a component must be pre-loaded axially during a torque-to-turn test. Breakaway torque and running torque can be tested under varying load conditions. All data can be uncollected and plotted, including the torque vs. force curves.

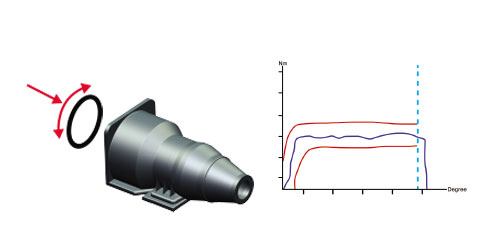

Application: Seal Pressing

Rolled or cut O-rings and seals are two common issues that can be greatly reduced by implementing Promess’ REMAP solution. Repeatable control of both the linear and rotational axes while monitoring force, torque and position through the entire operation will help produce a quality assembly every time.

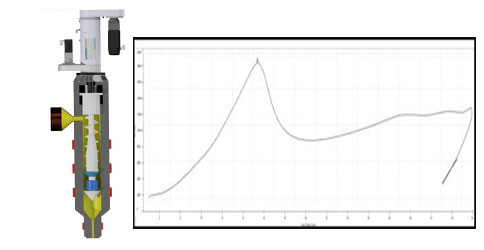

Application: Injection Molding

There are several critical factors that are encountered through the various steps of the injection molding process, all of which can be solved with a Protech Machine Injection Molding work cell powered by Promess, servo controlled REMAP system.

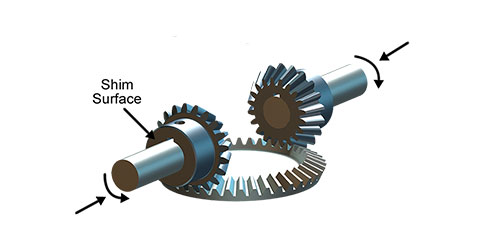

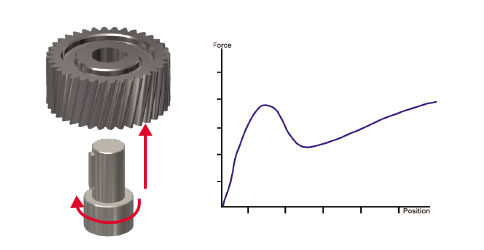

Application: Shim Select

The complex process of selecting shims is made simple with the REMAP. The axial load on the assembly is progressively increased until the turning torque reaches the target level. At this point, the exact gear height is measured and the required shim thickness is calculated.

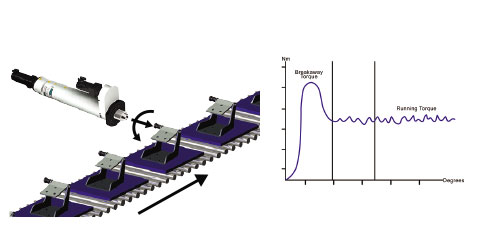

Application: Self-Actuating Torque Test

The REMAP is perfect for applications where you must feed out, couple to a component, and perform a torque-to-turn test. It is well suited to handle multiple part models. The Promess motion controller controls all motion which is performed by the REMAP.

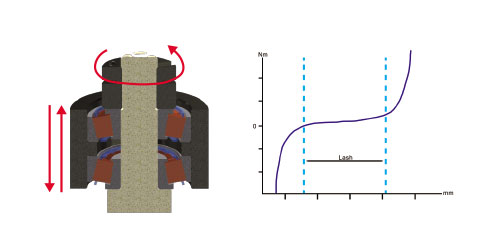

Application: Bearing Lash Adjustment

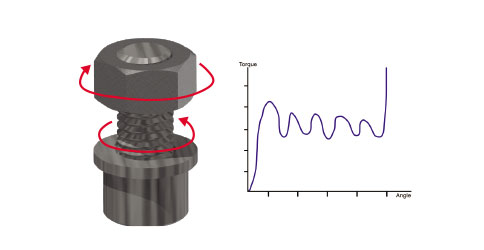

Application: Assemble to Torque

Application: Spline Alignment & Press

PRESS AND TORQUE CASE STUDIES

Application:

Automotive Belt Tensioner

Application:

Cross Thread Application

Application:

Assembling Universal Joints

What is Your Application?

Talk to one of our expert engineers or learn more about proving your application in our Process Development Center.