In the realm of manufacturing firearms for the US Military, precision is not just a desirable trait; it’s an absolute necessity. Each component of a firearm must meet stringent standards to ensure reliable performance in the most demanding situations. One critical aspect is the trigger mechanism – an element that demands consistency in force and operation across every single unit produced.

Enter the challenge faced by a manufacturer of handguns for the US Military: How to guarantee that each trigger pull on their firearms required precisely the same amount of force, every single time? Achieving this level of uniformity posed a significant challenge, particularly when dealing with such minute measurements.

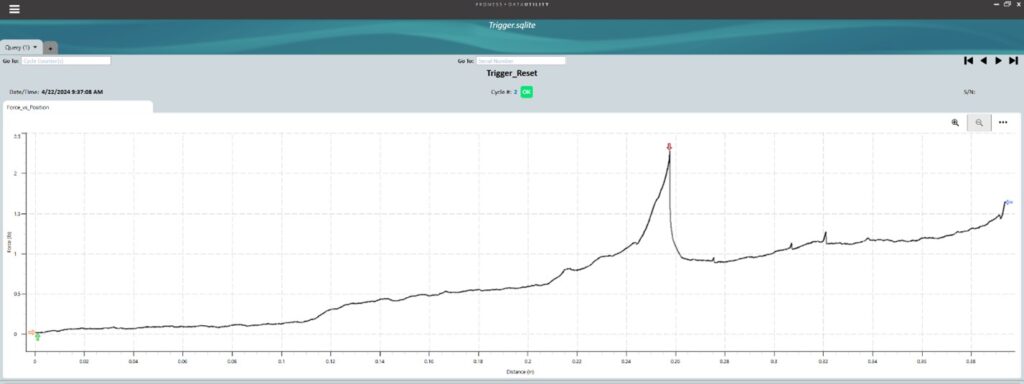

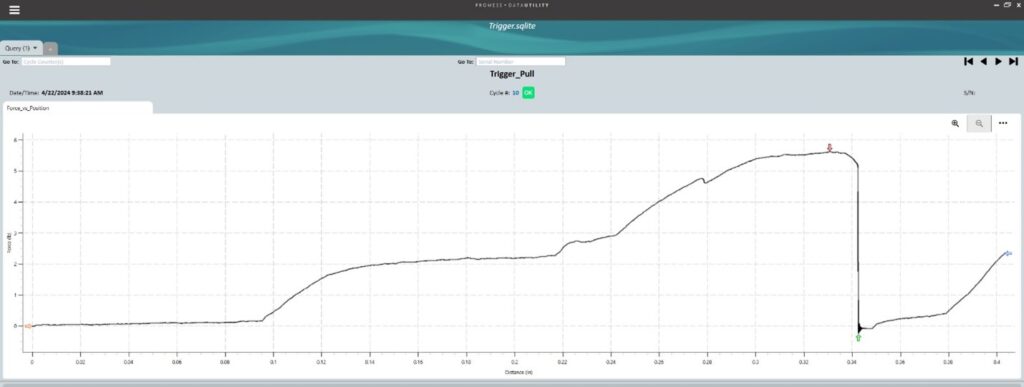

The manufacturer set a rigorous standard: a trigger force of 5.5lbs, with a tolerance of +/- 0.5lbs, along with specific parameters for trigger engagement and reset. Meeting these requirements demanded not only precision engineering but also advanced technology capable of accurate measurement and control.

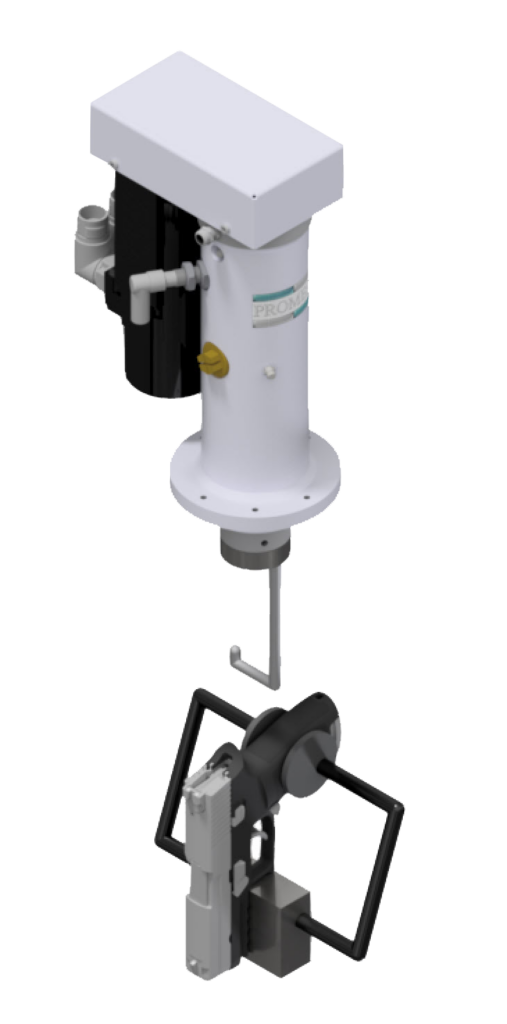

To address these challenges, the manufacturer turned to Promess, a leading provider of precision assembly and test systems. Promess’s solution involved leveraging their Electro-Mechanical Assembly Press (EMAP) outfitted with a high-precision 10lb external load cell, boasting an impressive accuracy of 0.5%. This setup allowed for precise control over force and positional accuracy, crucial for ensuring consistent trigger performance.

The EMAP system, integrated with Promess software, provided real-time monitoring of positional data and force measurements, ensuring that each trigger pull fell within the specified parameters. Any deviation from the set standards triggered immediate alerts, enabling swift intervention to rectify issues before they escalated.

The benefits of implementing the Promess EMAP system were manifold. Firstly, the manufacturer gained confidence in their ability to produce firearms that met the exacting standards of the military. Each unit underwent meticulous testing, with any outliers swiftly identified and addressed.

Moreover, the system facilitated continuous improvement efforts by providing comprehensive data on manufacturing processes. Armed with this information, the manufacturer could pinpoint areas for enhancement and implement corrective measures proactively, thus minimizing variations in production output.

Notably, the advantages extended beyond military contracts, as the same technology could be leveraged to enhance the quality of civilian arms. This versatility underscored the broader applicability of Promess’ solutions across various manufacturing domains.

Additionally, the manufacturer benefited from round-the-clock support from the Promess team of experts, ensuring prompt assistance whenever needed. This partnership fostered a collaborative environment where challenges were met with innovative solutions.

In conclusion, the integration of Promess’s EMAP system revolutionized handgun manufacturing for the US Military supplier. By ensuring precision and consistency in trigger performance, the manufacturer could deliver high-quality firearms with confidence. The seamless combination of advanced technology, meticulous testing, and continuous improvement efforts underscored a commitment to excellence that epitomized the partnership between the manufacturer and Promess.