In the intricate world of automotive manufacturing, precision is not just a requirement—it’s an absolute necessity. Every component must fit seamlessly into place, adhering to stringent tolerances to ensure the safety and reliability of the final product. However, when faced with challenges like the assembly of isolator bushings into upper and lower control arms, meeting these exacting standards can seem like an insurmountable task.

Imagine this scenario: The specifications call for a tolerance six times tighter than the combined tolerances of the components involved. With a specified total tolerance of ±0.6mm on the bushing position, the hurdle appears daunting, especially considering the inherent variability of the bushings themselves, which carry a tolerance of ±2.0mm. To compound matters, the stamped control arms, into which these bushings are to be integrated, exhibit their own considerable variations, further complicating the assembly process.

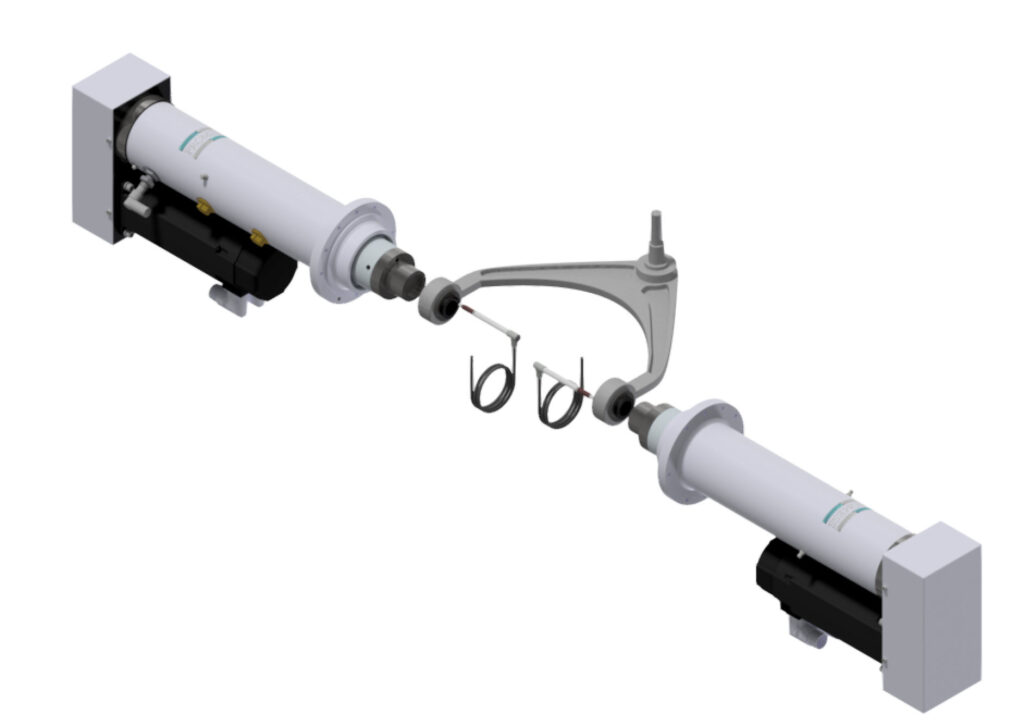

Enter Promess with their Electro-Mechanical Assembly Press (EMAP), armed with a revolutionary solution to this formidable challenge. Equipped with closed-loop feedback from external position transducers integrated into the fixturing and tooling, the EMAP introduces a paradigm shift in assembly processes.

This innovation allows for real-time measurement during assembly, compensating for part variations and ensuring consistent adherence to stringent tolerances. Remarkably, the EMAP maintains bushing positions to better than ±0.1mm, surpassing specified tolerances despite variations in control arms and bushings.

But the benefits don’t end there. The EMAP offers simultaneous press and gauge functionality, streamlining the production process and enhancing quality control measures. Its full force versus position signature monitoring ensures precise press-fitting of each bushing, with data stored for analysis, further bolstering quality assurance protocols.

Moreover, the incorporation of position transducers into the machine fixture enables real-time adjustments during assembly, maximizing precision and efficiency.

In conclusion, the integration of Promess EMAP into automotive assembly processes not only addresses tight tolerance challenges but also elevates overall production quality and efficiency. Through innovative technology and unwavering commitment to excellence, the automotive industry sets new standards for reliability and precision manufacturing. With solutions like the Promess EMAP, the possibilities for advancement and improvement in automotive assembly are limitless.